Even though dozens of tuning products exist in the diesel aftermarket, none of them are as powerful as EFI Live software. Available for ’01-‘16 Duramax-powered GM’s and ‘06-‘16 Cummins mills, EFI Live makes it possible for the end user to electronically infiltrate the factory ECU and TCM to access and alter data. No other tuning platform allows you to view and change so many different parameters. You can adjust timing, pulse width, rail pressure, cancel or revise pilot and post injection events, create a linear power curve, eliminate low-end smoke, limit boost, limit speed and anything else you can think of. There is literally a table for everything. Last but not least, EFI Live has the ability to data log any parameter(s) you choose, making this software that much more invaluable.

While EFI Live is extremely powerful, it can also be downright destructive in the hands of a novice or reckless tuner. This is why most enthusiasts (including us) prefer to have custom ECU and TCM calibrations built by reputable EFI Live tuning professionals, such as DuramaxTuner.com, Adrenaline Truck Performance, Hardway Performance and Silver Bullet Tuning, to name a few.

Follow along as we illustrate several ways in which EFI Live can improve the performance, drivability and reliability of a Duramax or Cummins diesel.

The Tool That Started It All

Before delving into the diesel market, EFI Live made it big in the Corvette and Camaro tuning world in the late ‘90s. However, once it was released for the 6.6L Duramax V8 it caught on like wildfire.

As soon as tuners began to perfect the ins and outs of the software, it quickly became the preferred method of tuning GM trucks, especially those making big horsepower, courtesy of larger injectors, turbochargers and common-rail pumps. Instead of Duramax-powered HDs that rattle, smoke and suffer from poor drivability, we now have trucks that are quiet, run clean and drive like stock until you hit the go pedal.

Harsh Timing Advance (Aftermarket Programmer)

Tuning files found on programmers from the early days of diesel performance were a bit barbaric, but they weren’t that way on purpose. Calibrators simply didn’t have access to all of the tables within the ECU, so they could only change a handful of parameters in the tables they did have access to.

This timing map showcases an aggressive ramp up in timing (in a diesel engine, “timing” refers to start of injection) on an aftermarket programmer. Timing spikes like this result in injector rattle and drivability issues — not to mention that excessive low-rpm timing is hard on connecting rods. To be fair, prior to EFI Live arriving on the scene (such as with this map), aftermarket calibrators built their tunes using the factory maps (only with tweaks here and there to get the desired effect). Suffice it to say that the map shown above is also very similar to what a factory timing map would’ve looked like.

Progressive Timing Advance (EFI Live)

Using the smoothing function in EFI Live’s tuning software, the same timing map can be altered to yield much more progressive timing advancement. The gradual timing increase shown here leads to a truck with no injector rattle and vastly improved street manners.

With nothing more than selecting the values that need to be smoothed and clicking the smoothing function, the behavior of one of the most important aspects of the engine’s injection system is much more refined.

All-or-Nothing Throttle (Aftermarket Programmer)

The all-or-nothing throttle experience was something a lot of enthusiasts had to live with before EFI Live came along. In the throttle position graph below, notice how steep the curve is.

At quarter throttle, full fuel is being commanded. With a throttle this touchy, you have to be very careful how you drive the truck. Excessive smoke, less low-speed control and poor street manners are par for the course with this kind of tuning. Of course, some enthusiasts prefer a touchy go pedal, but the majority of us like to use the full range of the accelerator.

Linear Throttle (EFI Live)

Making the throttle position graph linear is a key part of improving a truck’s drivability. Below you can see that 25 percent is quarter throttle, 50 percent is half-throttle, and so on. The graph is as it should be. On the flip side of this, some tuners use EFI Live to increase throttle response.

Case in point, when the LML Duramax debuted on ’11 model year GM trucks, a lot of owners complained that too much throttle input was required to get the truck moving. Despite having 397 hp and 735 lb-ft of torque on tap, the trucks felt lazy; so one of the first parameters DuramaxTuner changed (via EFI Live tuning) was the throttle position map, making the accelerator considerably more responsive.

Rail Pressure Command Spikes (Aftermarket Programmer)

One parameter that coincides with throttle position (along with engine rpm) is fuel rail pressure. Typically, as engine speed increases, rail pressure will follow. However, as is the case in the graph below, a tuning file pulled from an aggressive aftermarket programmer is commanding extreme rail pressure when it isn’t necessary.

Some aftermarket programmers even go so far as to command more than 40,000 psi of rail pressure. The problem with this is that no common-rail system is capable of producing more than 30,000 psi at the present time.

Smooth Rail Pressure Map (EFI Live)

An optimized fuel rail pressure curve below makes for a smoother driving truck and a quieter engine, but it is also easier on the components within the common-rail fuel system.

This type of map will minimize potentially harmful pressure spikes and allow the injectors to live a healthier life. It also keeps the system close to the peak pressure that was desired in the factory ECU calibration (i.e., keeping the injection system within the pressures it was designed to operate in).

Data Logging Functionality

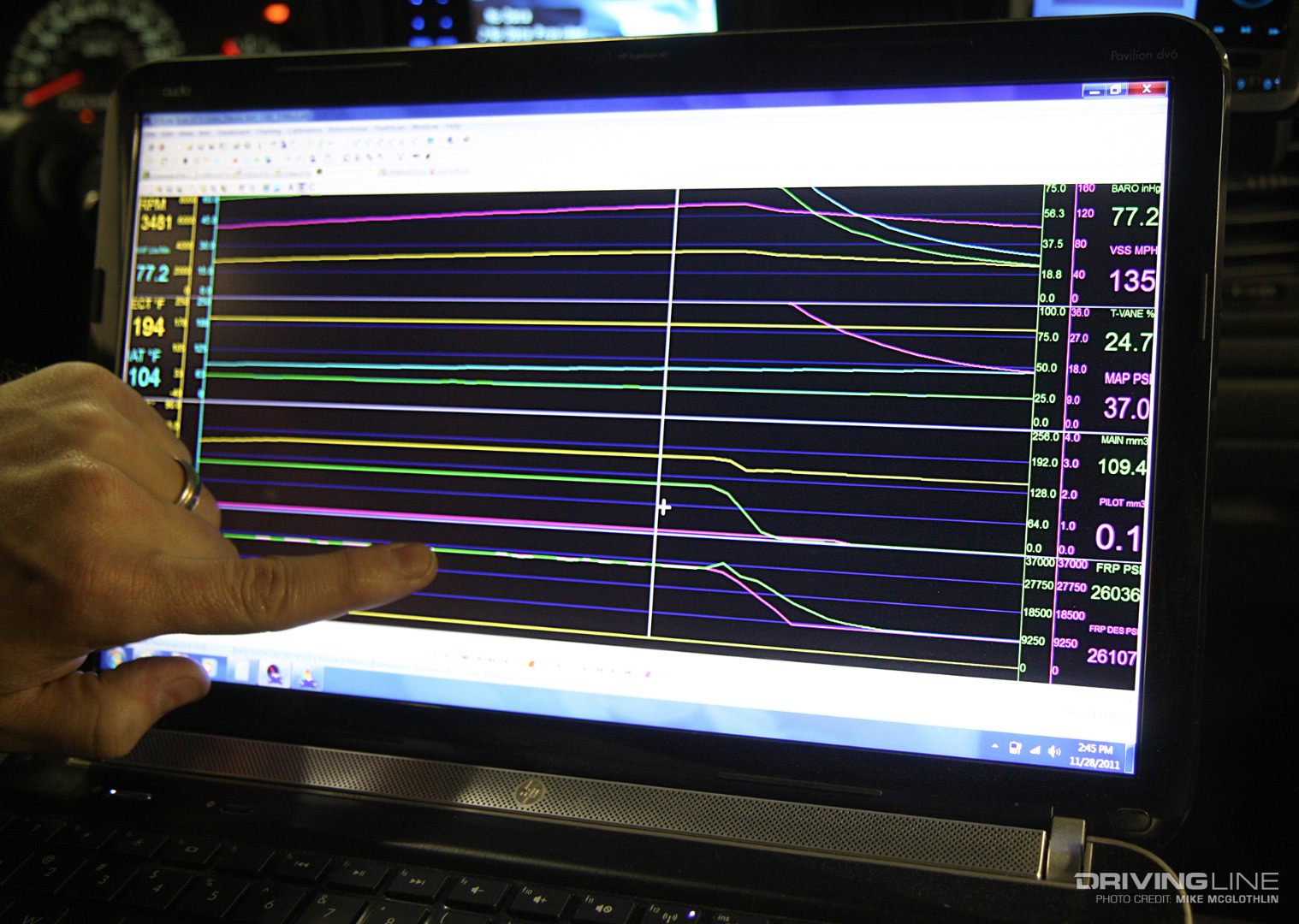

EFI Live data logging allows you to monitor engine performance, diagnose a problem or let you know if your tuning changes helped or hurt you. Below, a laptop is connected via an EFI Live FlashScan V2 device to monitor an LBZ Duramax on a chassis dyno (note that an Auto Cal V2 or Flashscan V2 device can be used in stand-alone form to data log a truck and that a laptop isn’t a requirement).

Here, the ability of the engine’s CP3 pump to maintain rail pressure while running a custom performance tune (calling for increased timing and pulse width) is being checked.

Peak Timing

In the days of old, a lot of folks didn’t know any better than to use multiple tuning devices on one truck, which became known as “stacking.” Combining a programmer that ramped up timing with a pressure box that increased rail pressure was a common occurrence. And while several of these combinations could make good power, people got into trouble when they either knowingly or (most often) unknowingly coupled two devices that ramped up timing together. The latter scenario could add in excess of 40 degrees of timing to an engine — a recipe for disaster.

The debut of EFI Live changed all of this as industry gurus dove headfirst into the software, tuned their personal trucks and armed themselves with the knowledge gained from tuning their own engines. The result is that timing, rail pressure and every other parameter of common-rail Duramax or Cummins can now be kept at safe levels, all while making the same (if not more) power. In the photo above you can see that just 30 degrees of peak timing is being commanded in an EFI Live-created performance tune.

On-the-Fly

The preferred method of navigating custom EFI Live tunes is through a hard-wired, rotary-style switch, primarily because calibrations can be changed on the fly. In Duramax applications the most common product is the DSP5 switch, which provides the end user five custom tuning calibrations to pick from (DSP4 and DSP2 switches are also available, which entail four and two custom tunes, respectively).

The same products exist for Cummins applications, albeit they’re referred to as CSP5 or CSP4 switches. Thanks to the on-the-fly versatility of these switches, a truck can go from a 50 hp tow tune to an all-out, 200 hp performance calibration with a simple turn of the knob.