If a turbocharged engine could hand out a best supporting actor award, it would be given to the intercooler. Positioned between the turbocharger and engine, and mounted behind the grille, an intercooler is a simple air-to-air heat exchanger that serves just one role- lower the temperature of compressed intake air. Yet, it is directly responsible for a multitude of benefits. Also known as a charge air cooler, an intercooler converts the compressed, super-heated, boosted intake air leaving the compressor outlet of the turbo into cooler, denser oxygen for the engine to ingest.

First and foremost, the advantage of cooling off compressed intake air is an increase in efficiency, horsepower, and torque. But, when cooler air goes into an engine, cooler air usually comes out as well, which means intercooled engines not only see lower intake temps, but lower exhaust gas temperature (EGT), too. The benefits of any engine seeing cooler intake air and decreased exhaust gas heat is that life is easier on both the engine’s internals and the turbocharger. Read on for a quick lesson in air-to-air intercoolers, as well as a brief look at water-to-air units.

Standard Hardware

In order to handle the amount of towing they’re rated for — and because enough room exists behind their massive front grilles — all modern diesel trucks utilize large air-to-air intercoolers with 3-inch thick (or wider) bar and plate style core designs (aside from the ’11-'17 6.7L Power Stroke, which uses a water-to-air system). Air-to-air intercoolers are popular due to their relatively low cost, effectiveness, simplicity and durability. Essentially, an intercooler is a heat exchanger that uses outside air to cool the post-turbo intake charge passing through it on its way to the engine. An intercooler consists of two end tanks with a finned core in the middle.

Aftermarket Intercoolers

On a diesel, an intercooler is vital in keeping the engine from seeing the kind of heat that can potentially melt pistons, damage valves or wipe out a turbocharger. While OEM intercoolers can get the job done for most folks, many in the performance game like to double or triple the horsepower of these trucks, which means they eventually upgrade to aftermarket units with larger cores and higher boost ratings (the AFE cooler pictured below is rated for a whopping 200 psi). While 100-to-200-degree drops in EGT are the norm when adding an aftermarket intercooler, we’ve seen an air-to-air unit from BD Diesel cool EGT by 250 degrees in an over-fueled 5.9L Cummins application.

Aerodynamics and Flow-Through

Not all intercoolers are created equal. We’ve always found the Techni-Cooler systems from Gale Banks Engineering to be some of the best air-to-air intercoolers you can buy. Their designs incorporate better aerodynamic flow both internally and externally than most other products on the market. What do we mean by external flow? Rounded exterior edges (vs. the harsh angles found on sheet metal intercoolers) lead to smoother airflow across not only the intercooler, but beyond it. While all intercoolers will lower intake air temperature and EGT, some aftermarket units will actually block flow-through to the heat exchangers behind them (namely the radiator). Trust us, achieving cooler EGT by increasing coolant temperature is not a fair trade. For utmost piece of mind, we would opt for a Banks unit if we were on the hunt for an aftermarket intercooler.

Split at the Seams

This is what happens when you try to cram 80 psi of boost through an intercooler rated to handle 60 psi. The fabricated (sheetmetal) end tank’s weld separated from the core on this particular unit, which was being used on a strong-running, compound turbo’d street truck. A bang, followed by instant loss of all boost pressure and a truck that could hardly move under its own power was the result.

Ultimate Cooling = Water-to-Air

When copious amounts of fuel and boost are on tap, a simple air-to-air intercooler usually won’t suffice. Because the air leaving the compressor outlet of the turbocharger can climb above 500 degrees in truck pulling applications (shown below), water-to-air intercoolers are extremely common. By circulating water through the intercooler, the heat from the highly compressed air is transferred to the water. These systems are extremely efficient (very little boost drop), hence the relatively small size of the intercooler itself, and they’re only made more efficient by bringing ice into the equation. Thanks to this type of technology, it’s not uncommon for truck pullers to cool their intake charge from 500+ degrees to a cool 60 or 70 degrees before it enters the engine, as well as keep peak EGT at or below 1,600 degrees. The drastic drop in intake air temp provided by using ice can also yield gains of more than 100 horsepower.

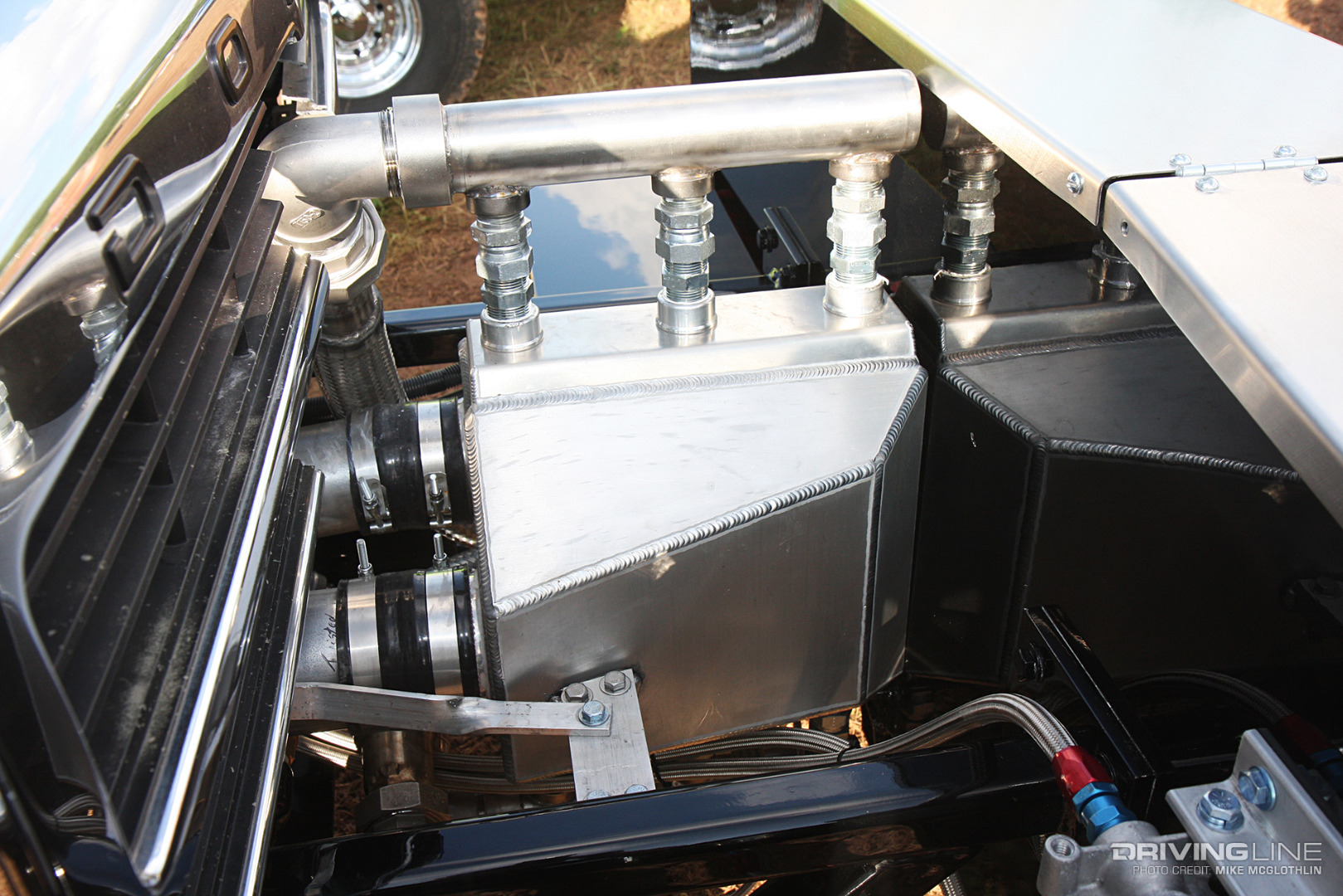

Putting Intake Temps on Ice

For a water-to-air intercooler system to work, a multiple-core heat exchanger, reservoir and water pump are required. Since most pulling trucks are fitted with a front weight box, most sled pullers use a portion of this space for the reservoir and/or ice storage required for their system. During the process of dropping intake air temperatures from as much as 600 degrees to 60 degrees, it’s not uncommon for 50 to 80 pounds of ice to be consumed per hook.

Factory Water-to-Air System

With the ’11 6.7L Power Stroke, Ford was the first manufacturer to bring water-to-air intercooling technology to the OE segment. Utilizing this type of intercooler design required a secondary cooling system separate from the engine in order to work. And work it does. The factory cooler is known to be very effective in both stock and higher horsepower applications. While the factory water-to-air intercooler is sufficient for most owners’ needs, the aftermarket unit shown below (available from No Limit Fabrication) is said to drop EGT by as much as 100 degrees over the stock cooler.

Extreme Intercooling, Simplified

Eliminating the piping associated with most high performance water-to-air intercooler systems, Wagler Competition Products offers this billet water-to-air unit, which sits in place of the factory intake manifold on Duramax mills. Made from 6061 aluminum and custom CNC-machined, it features a billet coolant tank and is port-matched to the company’s competition cylinder heads. This water-to-air intake can be found on several Duramax engines making north of 2,500 hp.

A Must-Have Item

For turbocharged vehicles that came non-intercooled from the factory such as the 7.3L Power Stroke-equipped ’97 F-350 pictured below, installing one is one of the first upgrades you should make. On top of cooling down cruising and peak EGT considerably, installing a massive Spearco unit in our own old body style Ford increased the truck’s torque output on the chassis dyno, and we also noticed a very minimal drop in boost (just 2-3 psi).

Water Injection

Beyond the cooling that an intercooler provides, there is also water injection. Throw in a 50/50 mix of water/methanol, and you can see sizable power gains. More on that at another time.