The lift pump. While nowhere near as glamorous as a billet wheeled turbocharger, a polished intake or a second injection pump, this component is as vital as it comes in the horsepower game. For diesels, lift pumps are the unsung heroes of their respective performance world. In addition to making big horsepower a reality, they add reliability to the entire fuel system, yield improved filtration over stock and (if electric) offer infinite adjustability over fuel pressure. In this day and age, it’s actually rare to peer under a diesel powered pickup and not see an aftermarket lift pump system bolted to the frame rail.

What They Do

The job of a lift pump is to supply low pressure fuel (from the tank) to the injection pump on the engine. Most lift pumps, aftermarket or OEM, provide between 8-to-15 psi worth of supply pressure (aside from the 7.3L, 6.0L and 6.7L Power Stroke engines, which call for 45-to-65 psi). From there, the injection pump or injectors (depending on which engine and injection system the engine has) pressurize the fuel that makes its way in-cylinder between 15,000 and 30,000 psi.

Without being supplied low-pressure fuel via the lift pump, the injection pump would have the added job of pulling fuel all the way from the fuel tank (which is the case in Duramax applications). Without adequate diesel feeding into the low-pressure side of the injection pump, its life span is greatly reduced. Continued fuel starvation will eventually damage the injection pump and possibly hurt the injectors.

When You Need One

Anytime you plan to pursue more power than what your truck made in stock form, a lift pump is a good idea. Because the injection pump and injectors are arguably the most vital components in a diesel engine, keeping them supplied with plenty of fuel keeps them cool, lubricated and functioning properly. In scenarios where the factory lift pump is on its way out, an aftermarket lift pump is the best possible upgrade.

Take the 5.9L Cummins found in ’98.5-’02 Dodge Ram 2500 and 3500’s for example: these trucks were equipped with a lift pump notorious for premature failure. When the lift pump checks out and 0 psi of fuel is supplied to the VP44 injection pump, it too bites the dust.

Why You Need One

In the grand scheme of things, an aftermarket lift pump system is a key element in making horsepower with a diesel. They provide higher flow rates and stronger pumps that can keep up with the demands of modified injection pumps and larger injectors.

In addition to being the catalyst for making horsepower, complete aftermarket kits provide added fuel filtration, improved water separation and their supply pressure can be adjusted. If you own a Duramax, an engine that was never offered with a factory lift pump, an aftermarket lift pump system will prolong the life of the CP3 injection pump on ’01-’10 models and especially the CP4.2 pump found on ’11-’16 GM trucks.

The Best System for You

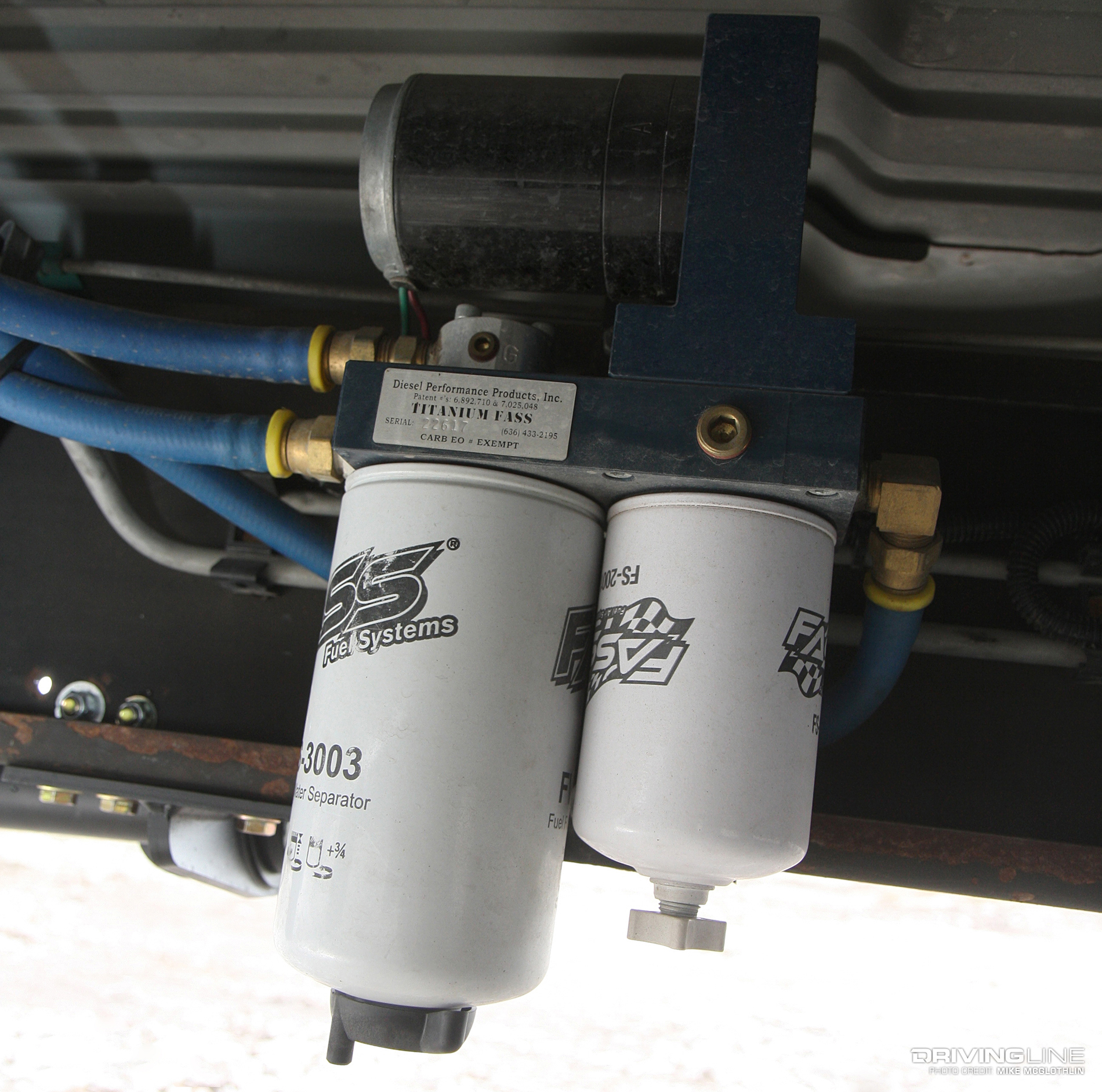

This varies depending on your application, but for the most part a complete (all-inclusive) lift pump system is best in terms of affordability and an easy installation process. Systems from FASS, Fuelab and AirDog provide you with everything you need from the tank to the injection pump (pump, lines, filters, wiring) and are available for all late model diesel trucks.

As a general rule of thumb, for most Duramax, Cummins and ’08-current Power Strokes, a 95 or 100-gph kit will support 500-to-600 hp, a 150 to 165-gph system will handle up to 800-to-900 hp and a 200-gph or more pump can support north of 1,000 hp.

For the HEUI injection systems found on the 7.3L and 6.0L Power Stroke engines, higher pressure fuel supply is required (65 psi). For the 7.3L, we recommend the standard or competition systems from Irate Diesel Performance for trucks in the 400-plus hp range. For the 6.0L, we have quite a bit of faith in the 125-gph system offered from FASS, which is right at home in 550-plus hp Super Duty's.

This is what most complete lift pump systems look like:

They come with everything you need to install them, including the lift pump, fuel filter, water separator, filter base, filters, fuel line, fittings, elbows, mounting bracket(s), wire harness and fasteners.

Anytime you’re upgrading (or replacing) injectors or injection pumps, it’s good practice to add or improve the lift pump. This not only preserves the life of your new injectors or pump(s) by keeping steady fuel pressure on tap for them to use, but it also provides added filtration and better air removal than what OEM components provide.

This is the latest generation high-pressure injection pump in the OEM segment: the CP4.2 from Bosch. It’s capable of producing up to 30,000 psi and is used on ’11-’16 Duramax engines and all ’11-current 6.7L Power Strokes.

Like all diesel-powered GM trucks (’01-‘16), no factory lift pump exists to feed low pressure fuel to the injection pump—and many are beginning to blame this engine’s lack of a lift pump for why these pumps are failing at ever-increasing rates. By comparison, CP4.2 pump failure is rare on the 6.7L Power Stroke, an application where the pump benefits from a lift pump supplying it 55 psi worth of fuel pressure.

One of the most popular aftermarket lift pump fuel systems is the AirDog line produced by PureFlow Technologies.

Systems start with units that flow 100-gph (stock to 500hp), upsize to 150-gph or 165-gph systems (up to 800hp) and culminate with a 200-gph kit (800-plus horsepower). While the 100-gph units are popular, the 150-gph and 165-gph systems are most common as they provide room for growth if a diesel owner decides to go beyond the 500hp mark.

FASS is another major player in the aftermarket fuel system game. One of its 150-gph Titanium series units for a Duramax application is shown here, which supports trucks making between 600 and 900hp.

Because the Duramax-powered GM’s didn’t come from the factory with a lift pump, adding one of these systems alone can greatly improve the life of the injection pump, not to mention add a few ponies. For this very reason, bolting a lift pump system to the framerail is one of the first modifications that Duramax owners make.

For most fuel system installs, dropping the tank is a requirement for an aftermarket lift pump system install. This is especially true for fuel systems that employ what’s known as a draw straw, or suction tube (pictured), which is what the lift pump pulls fuel through.

To get away from potential “low fuel in tank” issues (where a draw straw simply cannot reach the fuel on the bottom of the tank), many enthusiasts resort to a sump setup. Fuel tank sumps install in the lowest point on the tank and allow all diesel present to be scavenged for the lift pump to use.

A bonus is that most sump kits can be installed without dropping the tank and can be had for less than $200.

If you know which lift pump, what diameter and length fuel hose and fittings you’ll need, piecing together your own electric lift pump system can be a lot of fun. However, if you go this route, know that the entire system needs to revolve around the lift pump you choose and what its requirements are. For instance, with the system pictured being based around using an Aeromotive A1000 pump, its builder made sure the pump mounted below as close as possible to the fuel tank and that -10 fuel hose was used to supply fuel to the inlet of the pump.

In these kinds of DIY jobs (and when a serious pump like an A1000 is being used), the fuel return side should be upsized as well. On most trucks, you can repurpose the factory supply fitting atop the tank as the return (being that this fitting’s diameter is usually larger).

One of the best ways to showcase all the benefits of an electric lift pump system can be found when one is installed on a ’94.5-’97 7.3L Power Stroke. These engines came with a cam-driven, mechanical lift pump that sat under the turbocharger in the lifter valley.

It’s notorious for only being able to provide 35-to-45 psi of supply pressure to the injectors, not to mention causing premature wear on the cam lobe that’s used to drive the pump. An electric fuel system rids the valley of the mechanical pump, mounts an electric pump along the frame rail, and supplies 65 psi of fuel pressure (what is recommended on the 7.3L engine) to the injectors. The result is a longer service life from the injectors and an engine that sees a bump in horsepower.

For folks making big power with their diesels, the A1000 fuel pump from Aeromotive is a popular option.

This pump (which is diesel fuel rated) calls for massive, 5/8-inch fuel line to feed it, is incredibly durable in both competition and daily use and has proven capable of supporting up to 1,500hp in the gas world. We’ve seen them on countless trucks in the 800-plus horsepower range, as well as on dozens of daily drivers (our own 550hp ’97 F-350 being one of them).