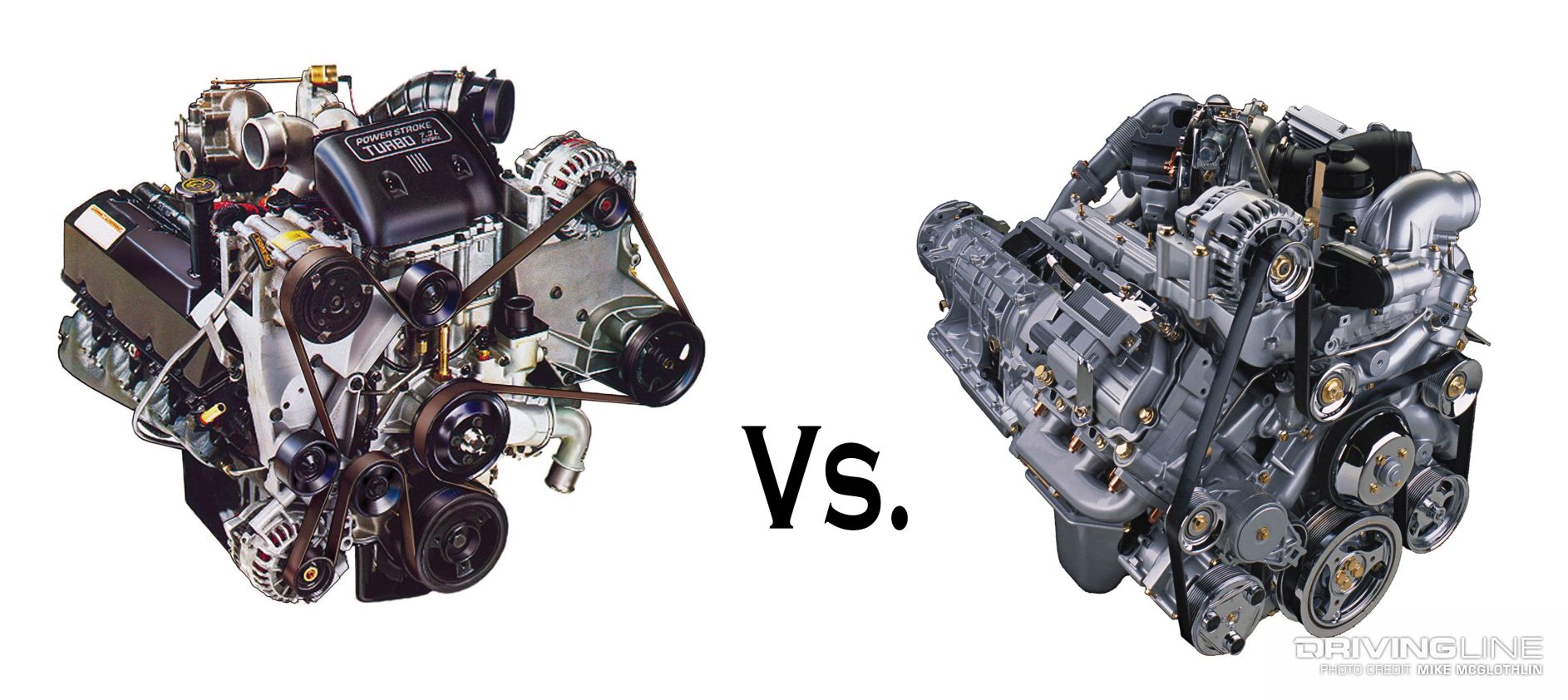

Statements like “The 7.3L was the best Power Stroke engine” and questions like “Why don’t they bring back the 7.3L?” are common among many Blue Oval loyalists who’ve been around the diesel game the last 15 to 20 years. They witnessed the phasing out of Ford’s first Power Stroke in favor of what proved to be a very infamous replacement: the 6.0L Power Stroke. After relentless recalls, dozens of technical service bulletins and the almighty power of word of mouth, it didn’t take long for the public to learn about all of the 6.0L engine’s problems: blown head gaskets, cracked EGR coolers, failed EGR valves, sticking turbos and bad injectors, just to name a few.

We're going to give you the facts along with some history on both engines. Which one will come out on top? Read on to find out.

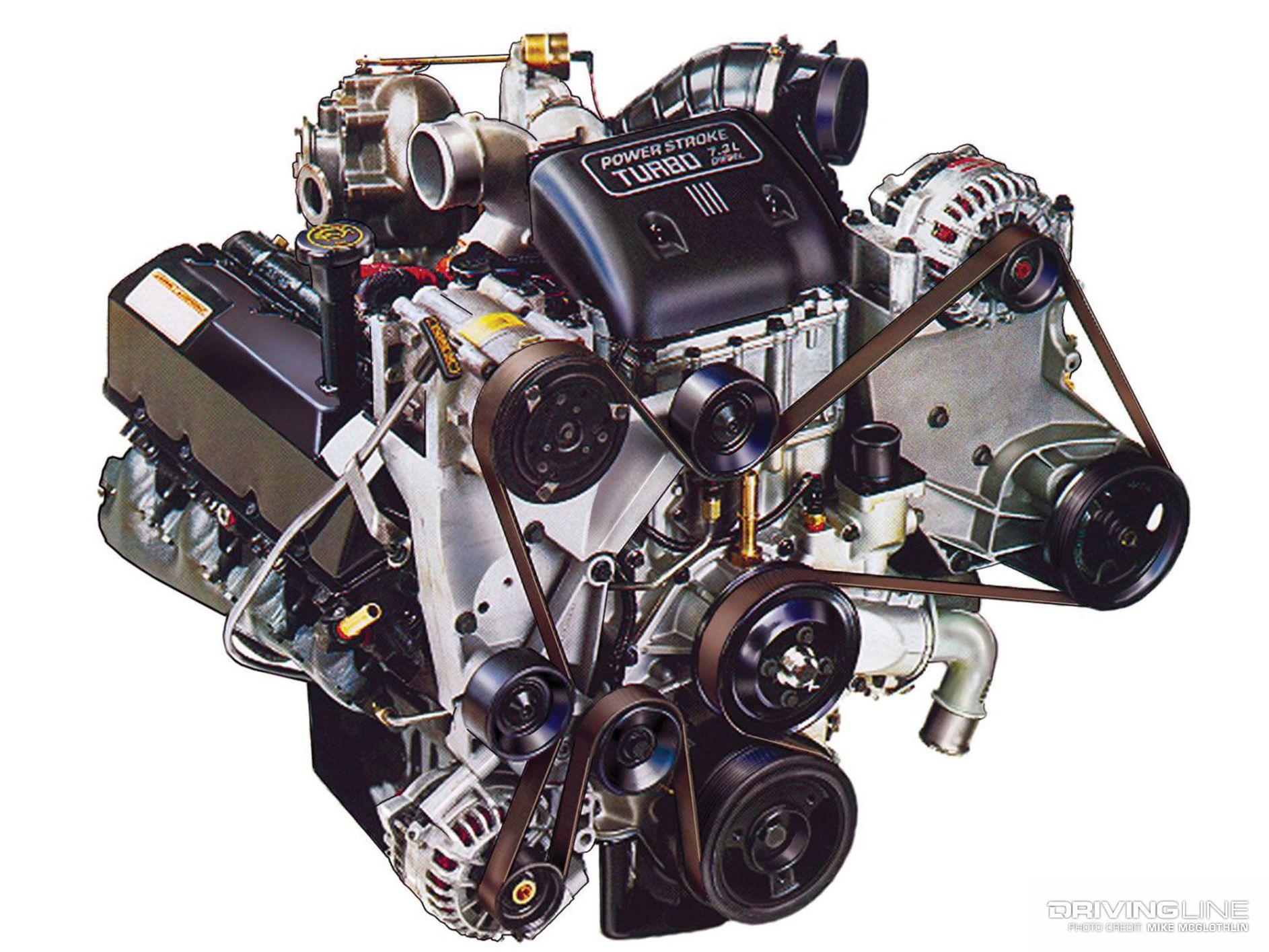

Why Did They Stop Building the 7.3L?

Emissions. In order to meet lower NOx emissions standards that were set to go into effect in 2004, Ford decided the 6.0L engine would be the best way to meet the new rules. The 365 cubic inch V-8 would feature EGR, a more efficient fuel injection system, and a variable geometry turbocharger. While the basic architecture and design of the 7.3L probably could’ve been reused, there was no guarantee it would’ve lived with exhaust gas recirculation in the mix, or been made to make much more than 300hp. Remember, the 7.3L started out life in mid-1994 with a 210hp rating.

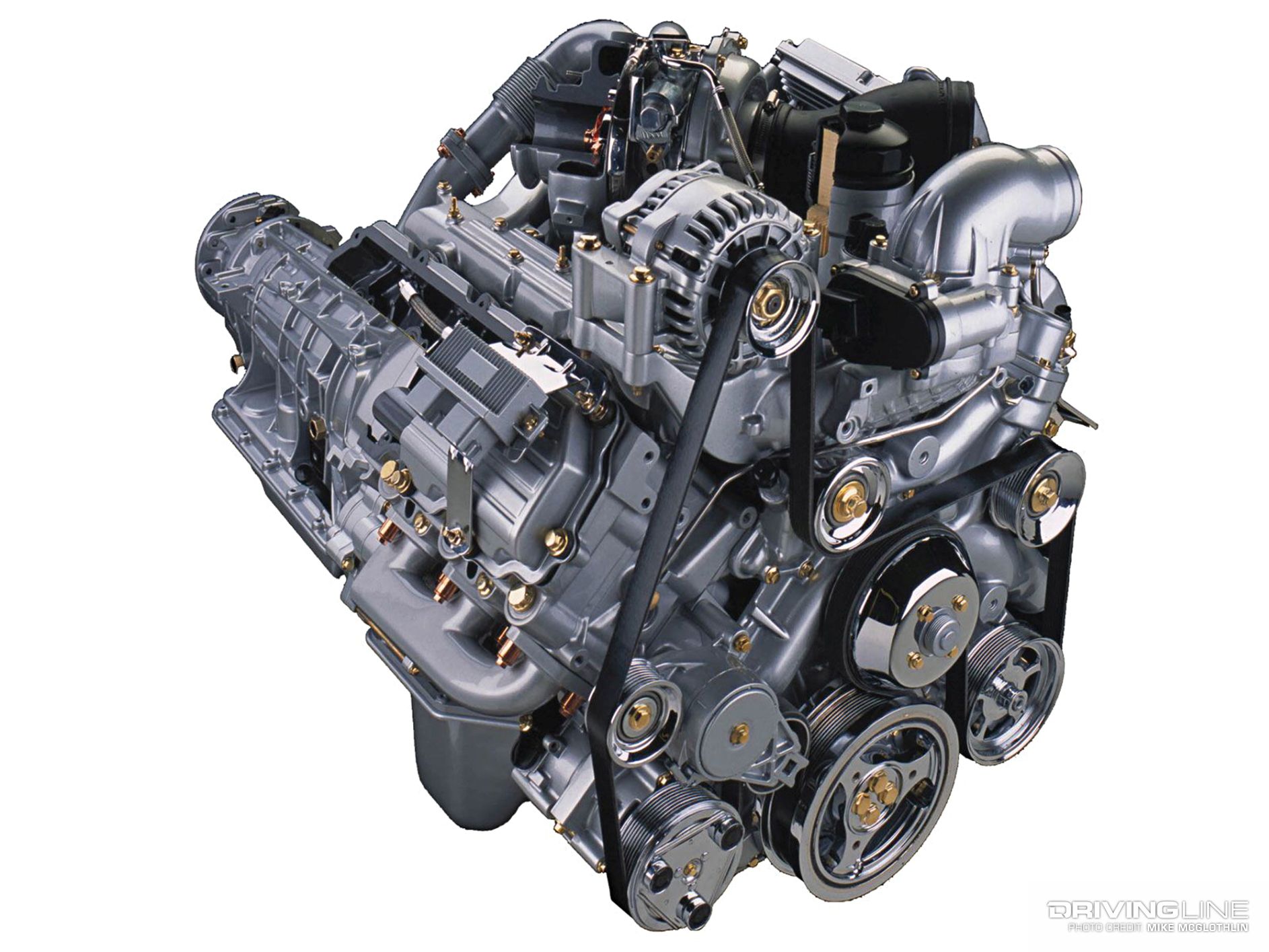

Why Ford Chose the 6.0L

By 2003, Ford was in need of a newer, more powerful engine. The 7.3L had already been uprated five different times just to get to the 275hp, 525 lb-ft mark—and it was still falling short of the 300hp 6.6L Duramax released by GM in 2001. The 6.0L offered 4-valves per cylinder and a higher pressure, hydraulically activated injection system—not to mention it packed 325hp and 560 lb-ft right out of the box (and was upped to 570 lb-ft starting in 2005).

Hard Facts

7.3L Power Stroke Specs:

- Displacement: 444ci

- Bore: 4.11 inches

- Stroke: 4.18 inches

- Valvetrain: Overhead valve, 2 valves per cylinder

- Compression Ratio: 17.5:1

- Factory Horsepower: 210hp (1994.5) to 275hp (2003)

- Factory Torque: 425 lb-ft (1994.5) to 525 lb-ft (2003)

6.0L Power Stroke Specs:

- Displacement: 365ci

- Bore: 3.74 inches

- Stroke: 4.13 inches

- Valvetrain: Overhead valve, 4 valves per cylinder

- Compression Ratio: 18.0:1

- Factory Horsepower: 325hp

- Factory Torque: 560 lb-ft (2003-2004) to 570 lb-ft (2005-2007)

Fixed Turbo

While the 7.3L Power Stroke was always fed by a fixed geometry Garrett turbocharger with a 60mm compressor wheel (inducer), it was available in three different forms in the pickup truck segment (from ’94.5 to '03). The turbo shown here is what you would find on a late ’99 to ’03 model year engine. The turbo’s fixed geometry nature contributes to its lack of responsiveness at very low rpm in comparison to the snappy spool up you’ll find on the 6.0L. However, while it was a hair on the laggy side, this turbocharger was extremely reliable at stock and slightly over stock power levels.

Variable Turbo

The Garrett turbo found on the 6.0L Power Stroke is of a variable geometry design (VGT). This means its turbine (exhaust) housing’s size can change depending on throttle position. The 6.0L turbo employs a vane-style turbine house in which steel vanes, commanded electronically, can instantly alter the velocity at which exhaust gasses hit the turbine wheel. Since the turbine side is what drives the compressor (intake side) on a turbocharger, the varying of the turbine housing allows the best of both worlds in terms of performance. At lower rpms, the housing is more restrictive (i.e. responsive), and at high rpm the housing is less restrictive (allowing full exhaust flow).

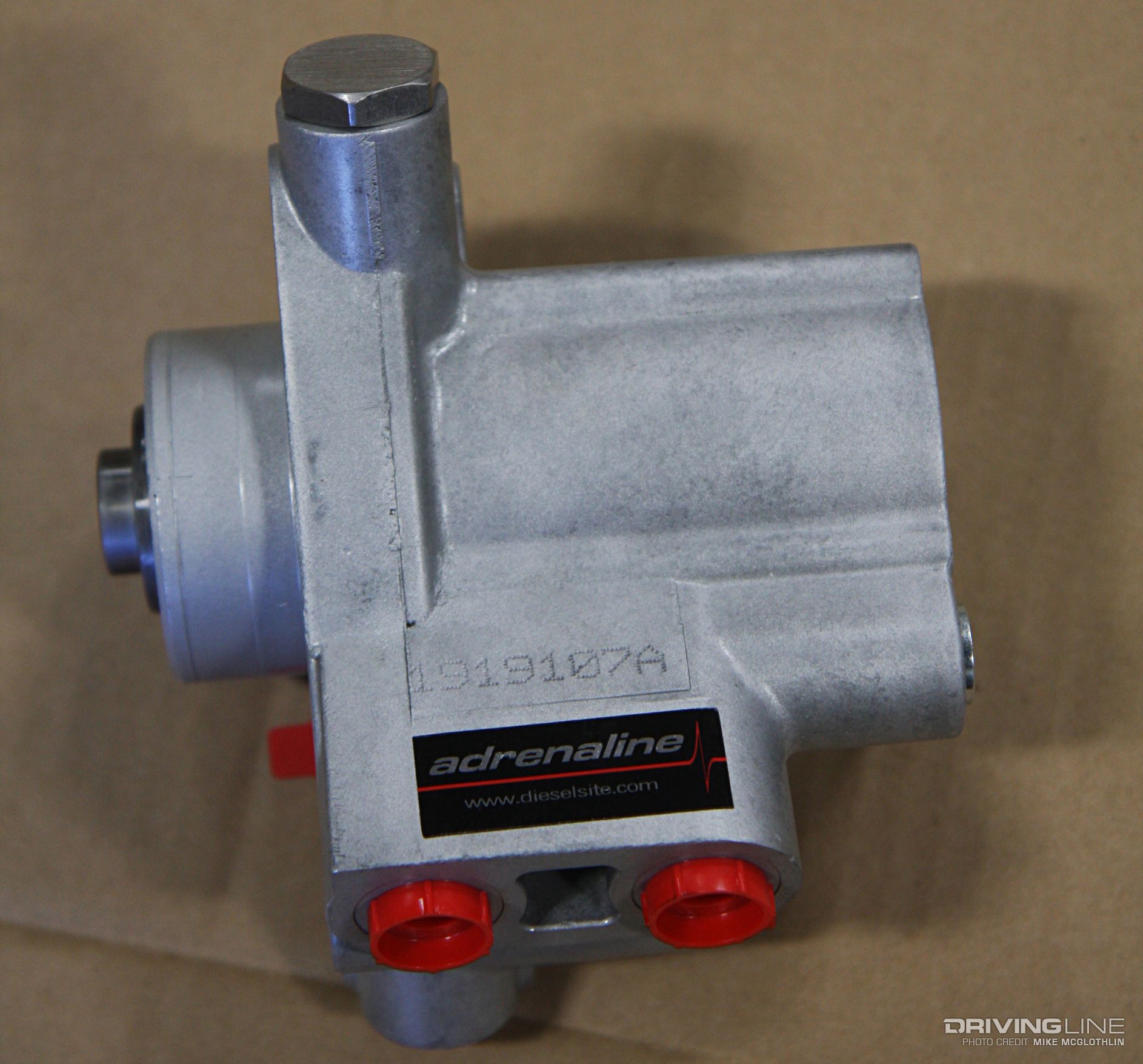

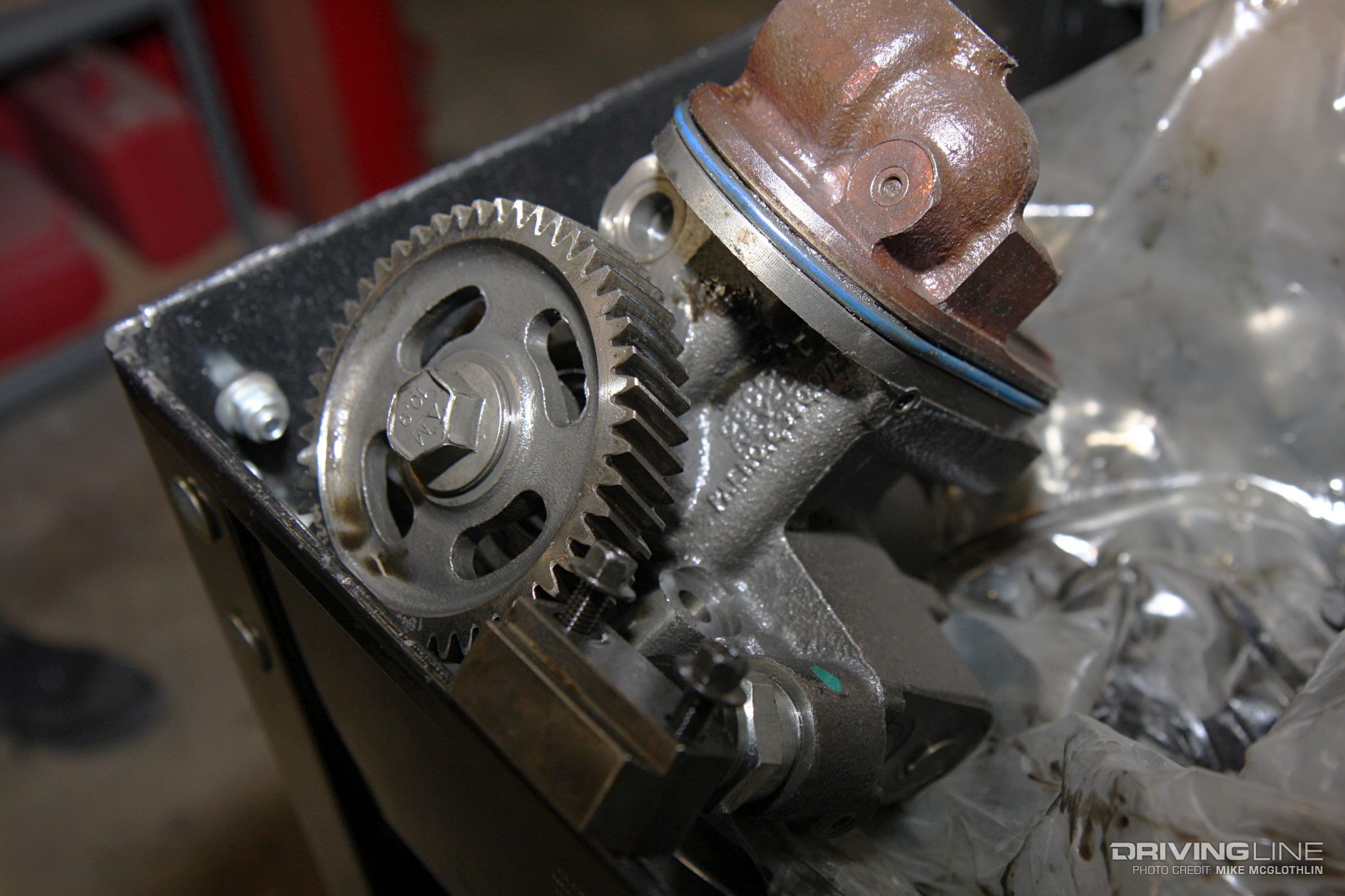

7.3L Injection

Because both the 7.3L and 6.0L Power Stroke engines utilize a hydraulically activated, electronically controlled, unit injector system (referred to as HEUI in the 7.3L’s case) in which engine oil essentially fires the fuel injectors, a high-pressure oil pump is employed. The 7.3L engine uses a gear-driven, fixed displacement pump located at the front of the lifter valley. Called the Adrenaline, the 7.3L high-pressure oil pump shown above is an aftermarket version built by DieselSite to support stock or larger injectors.

6.0L Injection

The high-pressure oil pump is also gear driven on the 6.0L, but the pump is positioned at the rear of the engine. Unfortunately, this pump is nowhere near as reliable as the units used on the 7.3L. When they fail, it’s a huge job to address it (as the pump actually resides beneath a cover under the turbocharger).

Poppet Valve

Being that oil is used to actuate the fuel injection event on a HEUI injector, the 7.3L injector body features an internal component called a poppet valve. This valve is what allows high-pressure oil to enter the injector (as high as 3,000 psi in factory form) and kick start the chain of events that culminates in 21,000 psi worth of injection pressure leaving the injector nozzle. The electronic solenoid up top is what gets energized (via the Injector Driver Module) when it’s time to fire. The poppet valve is one of the biggest wear items on 7.3L injectors, but they are known to last at least 200,000 miles.

Spool Valve

The 6.0L fuel injector operates similarly to the 7.3L unit, but the valve that allows high pressure oil to enter the injector body is referred to as a spool valve. Tighter tolerances, and a more technologically advanced injection system, allow the 6.0L Power Stroke to produce higher injection pressures (3,600 psi vs. 3,000 psi) and horsepower. Contaminants and dirty oil can wreak havoc on the spool valve, and it often doesn’t offer the same service life the poppet valve in the 7.3L injector does.

Connecting Rods

In terms of all-out horsepower, the 7.3L has a few pitfalls that keep it from being able to cope with big horsepower and torque. Engines produced between 2001 and 2003 are commonly equipped with powdered metal connecting rods, which are known to bend, crack, or break (shown above) due to increased cylinder pressure or fatigue at the 450 to 500-rwhp level. The forged steel rods found in ’94.5 through most ’00 model year engines are good for 600 to 650-rwhp before they’re on the ragged edge.

Bed Plate

Thanks to the 6.0L being equipped with a bed plate—and by design being a higher rpm engine—it’s capable of withstanding quite a bit more horsepower than the 7.3L. The stock connecting rods are good for as much as 750 to 800-rwhp, and the valve train doesn’t have to be upgraded until you’re making serious horsepower and boost (vs. the 7.3L where stiffer valve springs and stronger pushrods are essential when you start adding horsepower).

EGR

Of all the well-documented 6.0L Power Stroke problems, we will say that EGR-related issues are the worst of them. Even before you look into replacing the torque-to-yield head bolts with head studs, we’d address the factory EGR system’s shortcomings and/or observe regular cleaning intervals. Having said that, we also believe that most of the 6.0L’s problems can be avoided if proper maintenance intervals are observed and the owner knows the ins and outs of his or her engine. For instance, running the truck hard on occasion actually helps keep the turbo freed up and the EGR system from plugging. A gummed up EGR valve is pictured above, which can occur in as little as 20,000 miles if a 6.0L is allowed to idle extensively or is rarely driven aggressively.

7.3L Pros & Cons

Pros:

- 6 head bolts per cylinder (w/sharing)

- 290 to 325-rwhp with a chip

- No emissions system

- More reliable, fixed geometry turbo

- Good low-end torque thanks to 444 ci of displacement

- Higher resale value

- More reliable injection system

Cons:

- 210 to 275hp stock

- 4R100 automatic transmission (much weaker than the 5R110W behind the 6.0L)

- Weaker rods than a 6.0L (powdered metal units good to 450-rwhp, forged units good to 600-rwhp)

- Laggy, fixed geometry turbocharger

- No bed plate (main caps walk at higher power levels)

- One Achilles Heel: camshaft position sensor failure

6.0L Pros & Cons

Pros:

- 325hp stock

- 400-430-rwhp with a programmer

- Revvy, 4-valves per cylinder

- VGT turbo makes the engine responsive

- 5R110W TorqShift automatic transmission (very tough)

- Connecting rods can handle 800-rwhp

- Bed plate (crankshaft doesn’t budge)

Cons:

- 4 torque to yield head bolts per cylinder (w/sharing) leads to blown head gaskets

- Failure prone exhaust gas recirculation (EGR) emissions system

- Cylinder heads are known to crack

- VGT turbo that is prone to sticking open or closed

- Not as luggable under 2,000 rpm (not ideal for towing)

- Lower resale value

- Multiple injection system issues (STC fitting, injectors, air leaks, O-rings on stand pipes, HPOP’s)

Our Conclusion

Was the 7.3L truly a better engine? Sure. But that statement largely depends on what you’re basing that conclusion on. From a reliability, durability or simplicity standpoint, the 7.3L is hands down the winner. When it comes to horsepower, drivability and meeting modern day emissions standards, the 6.0L has it beat. Ultimately, both engines have their pros and cons. It’s up to you to decide which one checks more boxes in the categories that are important to you.