The salt of winter, the humidity of summer and a fair amount of neglect in between can do a number on your truck’s frame, axles and suspension. As someone who has a dented bed due to a corroded rear leaf spring shackle letting loose, you don’t want to ignore a rust issue.

This is how we chose to fight off the rust gremlins on our Ford F-350, and we’ve practically stopped all progression of this truck-killing cancer. Sure, it will never be completely eradicated, but we’ve finally got the problem under control. Now, a quick touch up is all we have to do from time-to-time to stay ahead of it.

So if you’re like us and don’t quite have the funds to do a full frame-off resto but have plenty of time on your hands—this is the job for you. Pick a weekend, grab a grinder, wire wheel, some scraping tools, your favorite rust-fighting chemical (see our recommendations below), a quality paint or undercoating and get to work!

From a regional standpoint, this photo represents something truck owners in the northeast and Midwest know all too well. Given enough time, rust will slowly eat away any exposed iron item bolted to your ride. As a northern Ohio truck, our F-350 grew up in the rust-belt (or salt-belt as we sometimes call it). Things didn’t improve much when we brought the truck home to Illinois, but we had a plan.

A slew of common household items and garage-kept tools is all that’s needed to perform the job. You’ll need a grinder with wire wheel, wire brush, 5-in-1 scraper, painter’s tape, masking paper, rubber gloves, and some sort of paint gun or empty spray container. Paint brushes get the call as well, to help evenly distribute the thicker areas of the rust reformer (once it’s applied).

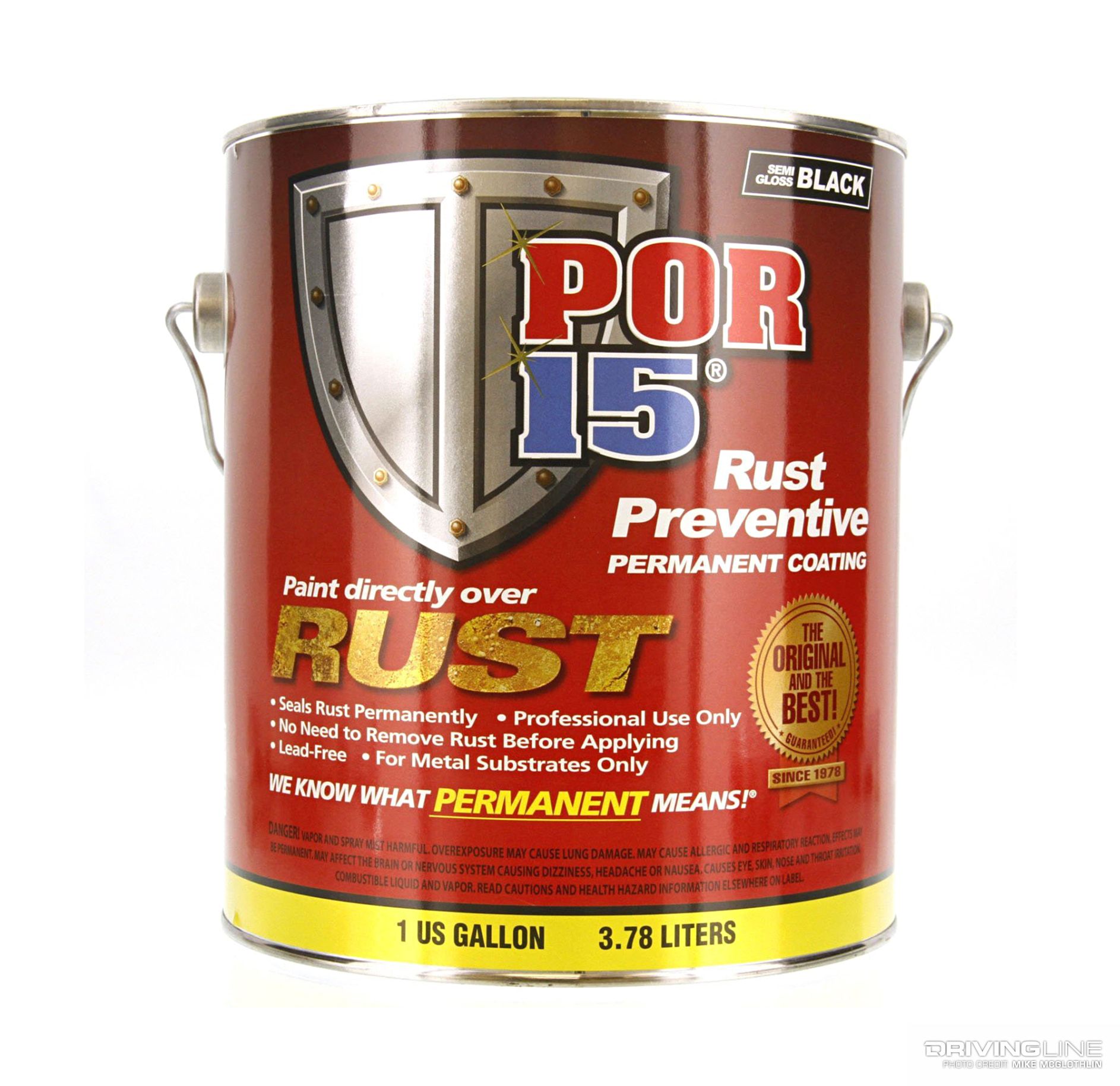

The most commonly used rust reformer in the pickup industry is a semi-gloss black product made by POR-15. The company’s rust preventative coating permanently seals rust, and better yet, once it’s applied its chemical makeup allows it to be further strengthened (not weakened) by the presence of moisture. This stuff should be applied in at least two (if not three) coats, and allowed 2-to-6 hours of dry time in between (note that the more humid it is, the quicker it will dry). Once treated, POR-15 recommends that you topcoat over it, due to its UV ray sensitivity. A one-quart container can be had for about $45 to $50 (you will likely need two to four) and you can find it at Summit Racing, 4Wheel Parts, or Napa Auto parts to name a few quality retailers.

Rust-Oleum’s rust reformer converts rust to a paintable (black) surface inside of 15 minutes. Unlike POR-15 reformer, it doesn’t have to be painted over after being applied, but Rust-Oleum does recommend applying a second coat if you don’t plan to apply paint. If you’re using an oil-based paint for a topcoat, a 4-hour wait period should be observed (but three days if using lacquer or aerosol paint). A bonus with Rust-Oleum’s product is that it is odorless. While you still need to wear hand protection, you can ditch the ventilator when applying it. You can snag this stuff at Wally World for roughly $6 to $8 per 8-ounce container, and it’s also available in 10.25-ounce spray cans (note that you’ll likely need five or six bottles per coat in order to treat a crew cab truck).

Made by SEM, Rust Mort uses phosphoric acid to convert existing rust into phosphate (a hard, black surface ready for painting). This stuff will take your breath away, so definitely wear some sort of ventilator or mask if you go this route. We used Rust Mort during our first treatment and we’re convinced it’s one of the best products on the market. After using it, practically all progression of the rust on our truck came to a standstill. Available by the quart (of which a typical truck will require about two containers per coat) or pint, Rust Mort can be had for roughly $25 to $28 per quart ($15 to $18 per pint) and you can get your hands on it via Summit Racing or O-Reilly Auto Parts.

Depending on the condition of your frame, axles, and suspension, you could easily spend an entire 8 to 10-hour day removing rust, old paint, or undercoating). Just like auto body work, most of the effort is built into the prep process. Where we had access, we used a grinder with a wire wheel. For tighter areas, we relied on a 5-in-1 scraper, wire brush, and even sand paper.

Once you’ve cleaned up the frame, axles, and suspension to the best of your ability, pressure wash everything and allow it to dry. We placed a few fans under the truck to speed up the drying process, in order to get on with the rest of the prepping.

Obviously, you won’t want everything underneath the truck painted or hit with rust reformer, so take time to cover up things like exhaust tips (or the entire exhaust system), diff covers, the transfer case, and the transmission. Aluminum foil and masking tape works great for this.

The best part about this job is that it can be as high-dollar or low-budget as you want it to be. Whether you’re using a gravity feed paint gun, a Hudson sprayer, or a repurposed tire shine spray bottle, the bottom line is to apply your rust reformer in every exposed area to get the same result: seal the rust and prevent the spread of it.

As for topcoat, we prefer a gloss black finish. There are a lot of automotive paints on the market, but we’ve always used Rust-Oleum’s Gloss Protective Enamel (PN 7779830). We find that it holds up a while, resists fading, and the ease of using the aerosol can is the biggest plus for us. Just shake, pull the cap off, and go to town. Most gloss or flat black paints can be had for $7 to $8 per 12-ounce can at your local auto parts house (make sure you grab at least a dozen, as it goes quickly).

BONUS PREVENTION TIPS:

1. Store your truck for the winter if you can, or at least park it in a garage.

Obviously, a lot of us can’t store our trucks for the cold months, hence one of the reasons for this article. Just remember vehicles that live indoors always avoid becoming scrap metal longer than ones living out amongst the elements.

2. Stay on top of the salt.

Once treated, and during winter, anytime the weather warms up (mid 30’s), wash your truck—or at least spray it down at the local car wash. We prefer to use the self-serve wash bays and we spend a lot more time spraying off the axles, underbody, suspension and frame than we do worrying about the windows or hood. Anything you can do to get the salt off is better than doing nothing—even if it’s only temporary.

3. Tackle it now!

The sooner you do it, the sooner you will stop the rust from spreading further.

4. Take a look around while you’re under the truck.

Use this project as an opportunity to go over the undercarriage with a fine-tooth comb and replace questionable items if necessary. For starters, inspect the condition of your brake lines, and check for fuel, oil, or transmission fluid leaks.

5. Wear eye protection.

During the prepping process, rusted metal particles will be flying everywhere so do yourself a favor and put on those dorky safety glasses you’ve got stowed away in your toolbox.