We’ve seen a lot of cool stuff in our years being involved in the diesel industry. Mega-horsepower sled pullers, 1,000-rwhp street trucks, 10-second quarter-miles.

The list of positives goes on and on. But, as much as we hate to admit it, we’d be remiss if we didn’t tell you that we’ve seen our fair share of carnage along the way. Catastrophic engine, driveline, and transmission failures are inevitable when engines designed to churn out 500 to 600 lb-ft of torque are dishing out three to four times that amount.

For those of you that like seeing battered, bruised and broken parts – this one’s for you. Here are 11 fails from the diesel truck world:

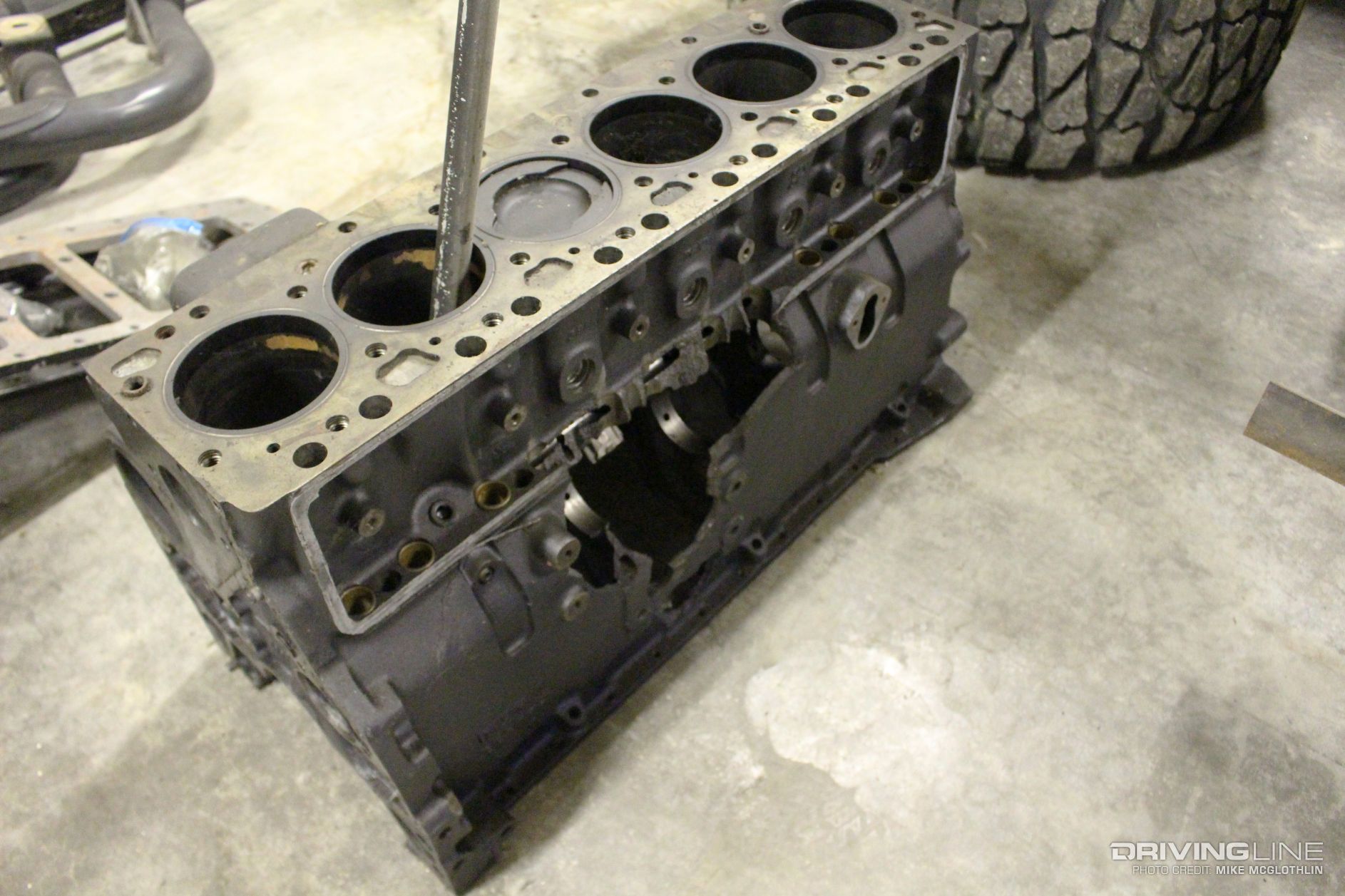

1. Holy Block

Despite having a rod leave the block, this picture is a testament to how strong the factory connecting rods are in the 5.9L Cummins 12-valve engine. Stock rods that have been shot-peened (and equipped with quality rod bolts) are capable of coping with as much as 1,500hp before bending. This mill was on its second full season of helping a 1,400hp 3.0 Class pulling truck make it down the track. This was without a rebuild in between, which is a big no-no in the sled pulling sport. Upon teardown, it was discovered that the rod wasn’t even the cause of failure, the engine had spun a rod bearing.

2. El Snappo

This is a common site when owners of ’01-‘03 7.3L Power Strokes pursue big horsepower (above 450hp). Most 7.3L engines produced during this time period left the factory with powdered metal connecting rods, as opposed to the forged steel units found in earlier mills (Note: forged rod engines can handle substantially more horsepower). Instead of bending, powdered metal rods are known to crack, oftentimes along the center of the beam. Add larger fuel injectors, aggressive programming, a little high mileage fatigue (more than 350,000 miles on the rod pictured above) into the mix, along with an over-rev scenario where the valves and piston kissed, and “El Snappo.”

3. Ejection

As in all motorsports, competitors are always sporting setups that live on the ragged edge in order to get into the winner’s circle. And with so many folks pushing the limit, the potential for carnage to surface is the one constant you can always count on. This wrist pin, complete with the small end of its respective connecting rod, exited the block of a 6.7L Cummins powered Ram at a truck pull. Chunks of steel departed the block just after the truck had been placed under maximum load (courtesy of the iron sled). While catastrophic, the two-pound projectile did clear the truck’s high-dollar injection pump on its way out of Dodge.

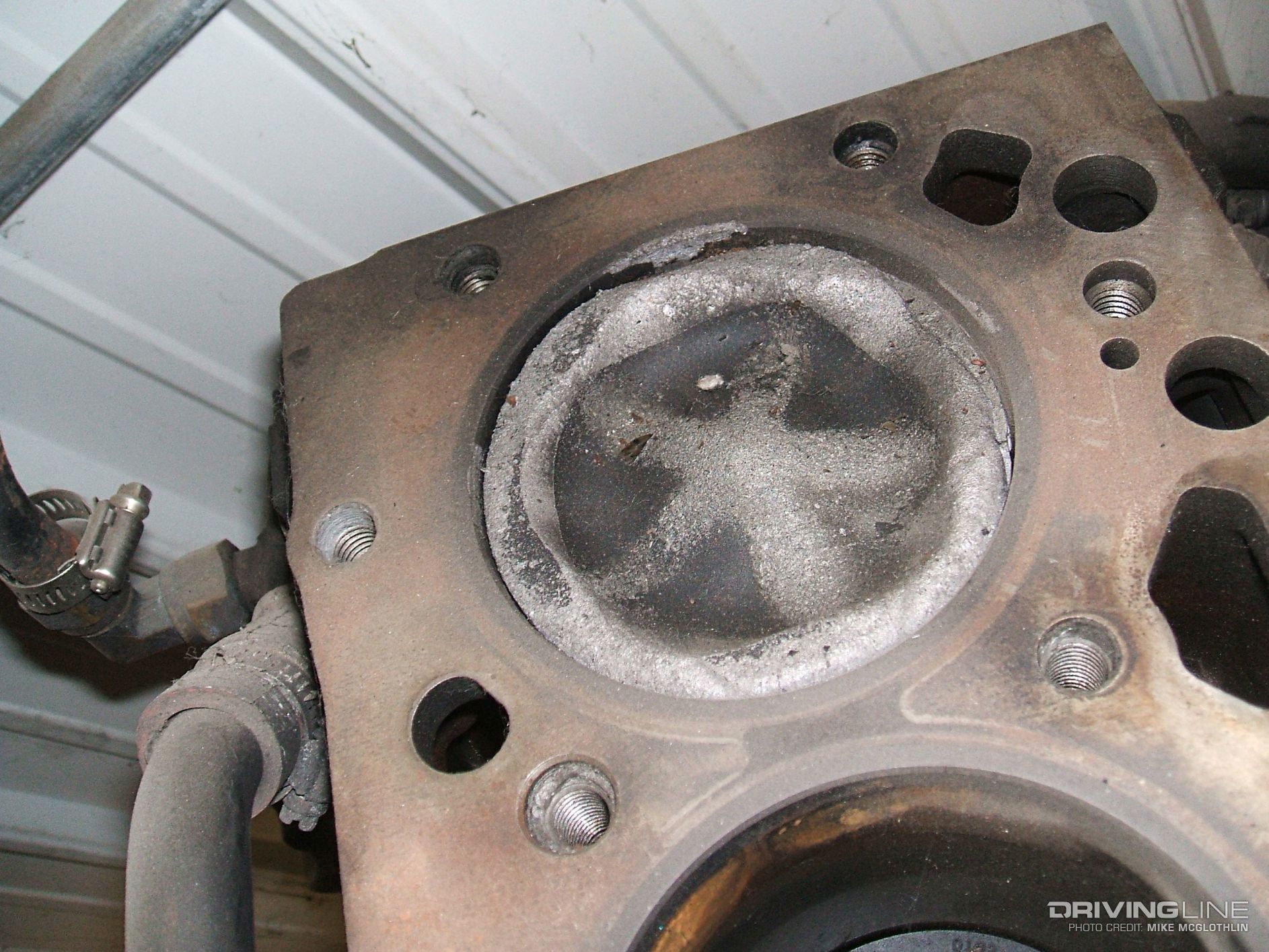

4. Fatal Flaw

Added horsepower and torque, increased timing, boost, higher cylinder pressure, and excessive heat are a recipe for disaster for any stock bottom end LBZ or LMM Duramax. In these versions of GM’s 6.6L V-8 (’06-’10 model years), the cast-aluminum pistons give up the ghost (crack) in the 600 to 650-rwhp range, which isn’t a difficult power level to get to with a Duramax. Needless to say, many enthusiasts have cracked pistons in LBZ and LMM engines over the years. Nine times out of 10, the piston cracks along the center line of the wristpin (as shown above).

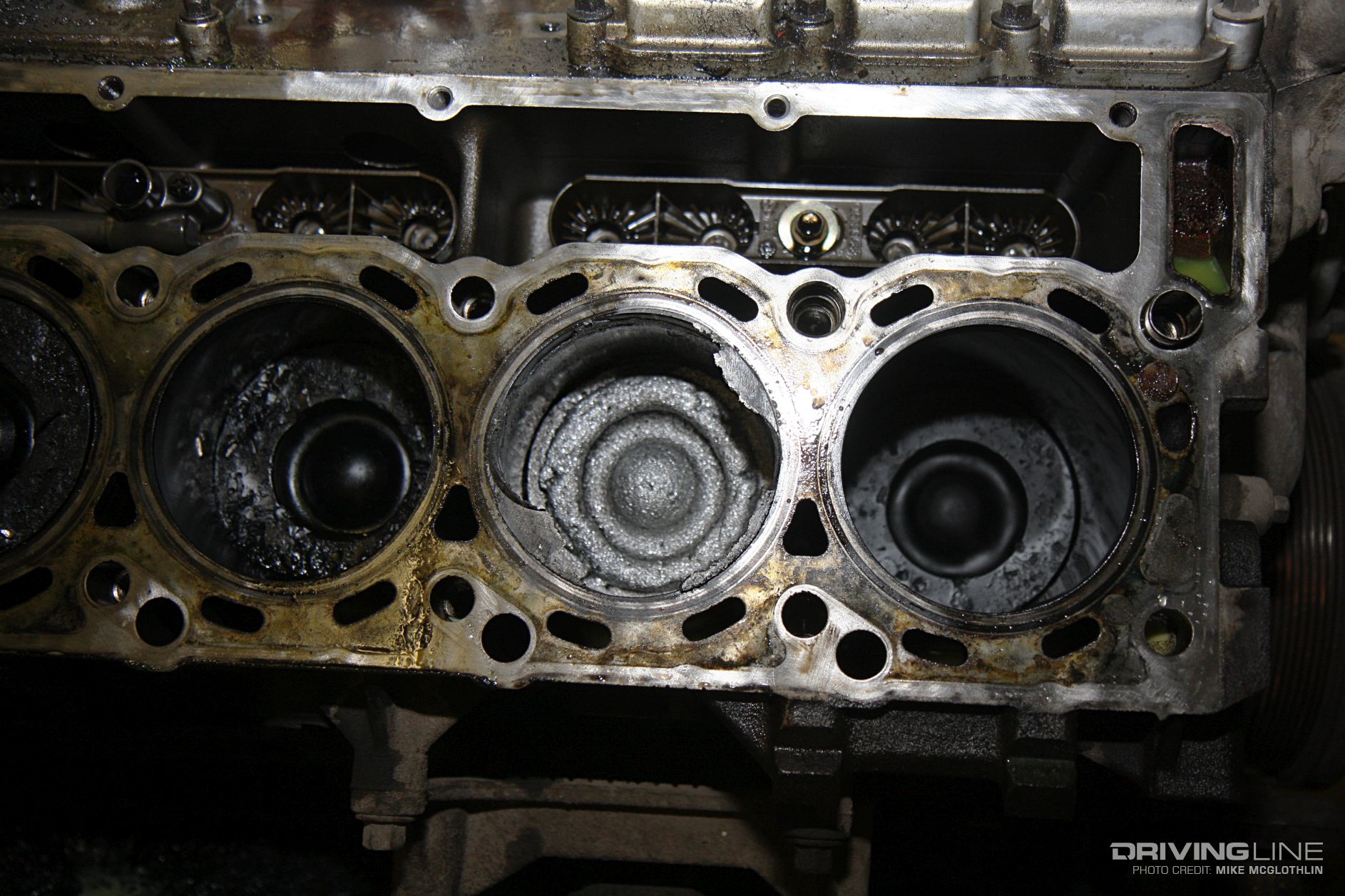

5. Total Meltdown

Before custom ECM tuning options existed for the common-rail 5.9L Cummins (’03-‘07), melted pistons were an everyday occurrence in the diesel industry (especially on ’04.5-’07 models). In most cases, running two devices that ramped up timing—oftentimes in conjunction with larger injectors—led to much of the carnage. Concoctions that maxed out rail pressure and/or extended the fueling duration of the injectors were the norm as well. Now that custom tuning is available and aftermarket companies and enthusiasts alike are better educated, engines make more horsepower, and do so in a much safer manner.

6. “It” Happens

Sometimes, unexpected failures occur and wreak all kinds of internal havoc. When the top compression ring worked itself loose from the number two piston inside a 5.9L common-rail Cummins, this was the end result. This type of failure is proof that anything can happen, at any power level, and even in Cummins mills, which are hands down the most reliable and durable power plants you’ll find in the diesel pickup segment. Further proving our point that anything can happen, this piston came out of a relatively low-mile Cummins (just over 100,000 miles) with nothing more than a mild programmer in the mix.

7. Cracked Nozzle = Complete Engine

Injector issues are not lost on the 6.0L Power Stroke engine (among other things), but this is an extreme case. Traced back to debris being present in the fuel supply system (i.e. lack of maintenance), the number 3 injector nozzle cracked in this particular engine. Adding insult to injury, the truck’s owner attempted to make it to his destination despite the truck misfiring, stuttering, and smoking like a freight train. With no fine atomization going on in-cylinder, the injector acted like a blow torch, dowsing the cylinder in diesel fuel and effectively melting the piston beneath it. If the truck owner hadn’t tried to make it that last 20 miles, he might not have needed a complete engine.

8. Torque Twist

It’s important to remember that with diesels torque is the killer of most parts (not horsepower). Needless to say, automatic transmission failures of all kinds run rampant in the diesel pickup world. This twisted input shaft came out of a 48RE automatic tasked with handling more than 1,500 lb-ft of torque being dished out by the 5.9L Cummins in front of it. With that said, input and output shaft failures aren’t typically as catastrophic as intermediate failures. When an intermediate goes, it distributes shrapnel throughout the rest of the transmission (fluid, clutches, gears, pump, torque converter), which usually means the only salvageable component is the transmission case.

9. Popped Collar

When ’01-present GM owners get serious about truck pulling and making big horsepower, they find the weak link within the AAM 9.25 front axle. As opposed to the locking hubs you’ll find on solid front axle Fords, GM’s incorporate a center axle disconnect (CAD). The component shown above represents what is left of the sliding collar that makes the CAD function possible. Under extreme load and torque, the collar is exposed to immense twisting and binding forces. When this baby goes, it typically explodes (just like this one did).

10. Rip Off

An unbalanced driveshaft on a truck built strictly for hooking to the sled can spell disaster on the chassis dyno. Such was the case for this sled-pulling Ford F-350 that typically sees a top speed of less than 30 mph. Brought up to highway speed (and with the transmission in Overdrive), all hell broke loose once the load from the dyno hit and the engine began making good boost. In a split second, the pinion yoke disintegrated, the driveshaft was turned into an L shape, and the tail housing was ripped off of the E4OD automatic.

11. Not So Sterling Axle

For those in the truck pulling in-crowd, campaigning a Sterling 10.5 axle (or 10.25 for that matter) is avoided like the plague. This rear axle sports a smaller pinion bearing and pinion shaft diameter than what is found on comparable axles (namely the popular Dana 80 or AAM 1150 found under Rams and GM’s). In addition, the Sterling 10.5’s inner bearing and race is even smaller in size than its 10.25 predecessor. Couple these weaknesses with 38-inch tires, a numerically high ring and pinion ratio, and an overall ring gear diameter that is smaller than what the competition is using and you get a lot of rear end failures in the dirt. We’ve even seen the differential break free from the axletubes.