As the trend of ever-tightening emission standards continued to force diesel engine manufacturers back to the drawing boards, some pretty neat advancements in turbocharger and fuel injection technology came about in the late 2000s. Case in point, by January 1, 2007, automakers had to meet the very stringent particulate matter standard of 0.01g/bhp-hr. On the NOx side of emissions, the EPA’s tougher nitrogen oxide standard began a three-year phase-in, which required all diesel engines to emit no more than 0.20g/bhp-hr by 2010. To clean up particulate matter, each of the Big Three added exhaust after treatment systems to their engines, which included a diesel particulate filter (DPF) and a regeneration function that required excess diesel to be burned to keep the DPF clean.

Thanks to the addition of a DPF, revised EGR system with more exhaust gases pumping through the engine and a few other subtle tweaks, GM’s class-leading LBZ basically became the LMM Duramax. Treated to 5 more horsepower, 10 more lb-ft of torque and propelling the all-new GMT900 platform for ’07.5, the LMM retained its title as the leader in the diesel pickup world with its 365 hp and 660 lb-ft rating. As for Dodge and Ford, their trucks would sport all-new power plants in order to comply with federal law. The 6.7L Cummins—an inline-six with a stronger block, bigger bore and longer stroke than the 5.9L—debuted in ’07.5 Dodge Ram heavy duties, complete with a variable geometry turbo, DPF and EGR. Ford would opt to meet the new emission standards with the Navistar-built 6.4L Power Stroke, a compound turbocharged V8 with common-rail injection, piezoelectric injectors, an EGR system with dual coolers and a DPF.

Though this period would be defined by how complex the emissions systems had become on the once-simplistic, diesel engine, all of them were packing more horsepower and torque than ever before. To find out how each manufacturer went about cleaning up emissions while simultaneously improving power, keep scrolling.

| Specs | ‘08 6.4L Power Stroke | ’07.5 6.6L LMM Duramax | ’07.5 6.7L Cummins |

| Configuration | V8 | V8 | I6 |

| Displacement | 390 ci | 403 ci | 408 ci |

| Bore | 3.87 inches | 4.06 inches | 4.21 inches |

| Stroke | 4.13 inches | 3.90 inches | 4.88 inches |

| Compression Ratio | 17.5:1 | 16.8:1 | 17.3:1 |

| Block | Cast-iron with bed plate | Deep-skirt, cast-iron | Deep-skirt, cast-iron |

| Rods | Powdered-metal | Forged-steel, cracked cap | Powdered-metal, cracked cap |

| Pistons | Cast-aluminum | Cast-aluminum | Cast-aluminum |

| Head(s) | Cast-iron with four 16mm head bolts per cylinder | Cast-aluminum with six head bolts per cylinder | Cast-iron with six head bolts per cylinder |

| Valvetrain | OHV, four valves per cylinder, single cam | OHV, four valves per cylinder, single cam | OHV, four valves per cylinder, single cam |

| Injection System | Siemens high-pressure common-rail, direct injection | Bosch high-pressure common-rail, direct injection | Bosch high-pressure common-rail, direct injection |

| Turbocharger | BorgWarner series sequential turbos | Garrett GT3788VA VVT | Holset HE351VE |

| Intercooler | Air-to-air | Air-to-air | Air-to-air |

| Emissions | Exhaust gas recirculation (EGR), diesel oxidation catalyst (DOC), diesel particulate filter (DPF) | Exhaust gas recirculation (EGR), diesel oxidation catalyst (DOC), diesel particulate filter (DPF) | Exhaust gas recirculation (EGR), diesel oxidation catalyst (DOC), diesel particulate filter (DPF) |

| Horsepower | 350 hp at 3,000 rpm | 365 hp at 3,100 rpm | 350 hp at 3,013 rpm |

| Torque | 650 lb-ft at 2,000 rpm | 660 lb-ft at 1,800 rpm | 650 lb-ft at 1,500 rpm (auto), 610 lb-ft at 1,500 rpm (manual) |

New and Improved Power Stroke

Image may be NSFW.

Clik here to view.

Ford released its 6.4L Power Stroke on January 1, 2007, along with a redesigned Super Duty, but called them ’08 models. Compared to the 6.0L engine it replaced, the 6.4L was a technological marvel. HEUI was finally ditched in favor of high-pressure common-rail injection, complete with state-of-the-art piezoelectric injectors. A series sequential turbo system (i.e. compounds), comprised of a variable geometry high-pressure charger and a larger fixed geometry low-pressure unit, provided for great drivability and at least 600 lb-ft of torque made available from 1,800 to 3,100 rpm. The EGR system’s capacity was essentially doubled and larger diameter (16mm) head bolts were employed to anchor the cast-iron 4-valve cylinder heads to the block—two major downfalls associated with the outgoing 6.0L Power Stroke.

Factory Compounds

Image may be NSFW.

Clik here to view.

Produced and supplied by BorgWarner, the series sequential turbo arrangement utilized on the 6.4L Power Stroke was a first for the diesel pickup segment. The compact compound system, which consumed much of the lifter valley, took its first gulp of air through a low-pressure fixed geometry turbo with a 65mm compressor wheel. The second stage of compression occurred after that at the 52mm variable geometry, high-pressure turbo. With both turbochargers running at full song, the 6.4L saw 42 psi of boost in stock form.

Switching to Common-Rail

Image may be NSFW.

Clik here to view.

Precise control, multiple injection events and higher pressure all make common-rail fuel systems the ideal choice for meeting the most stringent emission standards. In ditching HEUI for common-rail, Ford and Navistar ushered the Power Stroke name into the modern age. But the 6.4L one-upped the competition by being the first manufacturer to offer piezoelectric injectors (as opposed to solenoid valve units). Sourced from Siemens, the piezo units could pull off two pilot injection events before the main during each combustion cycle (and two post events following that), making the 6.4L nearly as quiet as the Triton gas engines Ford was offering at the time. The injectors were fed 24,500 psi of rail pressure from a Siemens VDO K16 high-pressure fuel pump that was mounted at the rear of the lifter valley.

More EGR, A DPF and Regen Cycles

Image may be NSFW.

Clik here to view.

Knowing that more exhaust gas recirculation would have to take place in order to meet the coming NOx standards, Navistar added two EGR coolers to the 6.4L Power Stroke. After exhaust gasses pass through both heat exchangers (17 inches of travel), they’re cooled from as much as 1,200 degrees to 111 degrees F upon entering the intake. More efficient EGR valve actuation was made possible by equipping the unit on the 6.4L with a more powerful DC motor. As for keeping the DPF from filling up with soot, a regeneration (cleaning) cycle that introduced extra fuel on the engine’s exhaust stroke resulted in most of the accumulated particulate matter being burned off.

LMM Duramax: The Emissions-Friendly LBZ

Image may be NSFW.

Clik here to view.

Unlike Ford and Dodge, GM didn’t need to turn to a full-on engine redesign in order to meet the 2007 emissions crunch. Instead it’d been planning ahead for years, prepping its 6.6L V8 not only for more emissions-control technology but more power. Though some changes were inevitable to meet more stringent particulate matter and NOx standards (DPF, more EGR, different ECM, updated injectors), much of the same basic makeup found in the LBZ can be found at the heart of the LMM Duramax. The deep-skirt cast-iron block is the same, the connecting rods and pistons are the same and slight coolant passageway improvements were the only alterations made to the cast-aluminum heads.

New Injectors, Same Injection Pump

Image may be NSFW.

Clik here to view.

Part of the recipe for cleaning up in-cylinder emissions was to improve the combustion process. This was done using new, six-hole nozzle injectors with a wider, 159-degree spray angle. The same suction-valve-equipped, 195-lph Bosch CP3 was used to produce as much as 26,000 psi of fuel pressure, though the CP3 was still void of a lift pump from the factory.

The Key to 90-percent Soot Reduction

Image may be NSFW.

Clik here to view.

In order to meet the 90-percent mandatory reduction in particulate matter emissions, each manufacturer had to add an elaborate exhaust after treatment system. Key components in each system consisted of a DPF, diesel oxidation catalyst (DOC) and active regeneration functionality. Like the 6.4L Power Stroke, the LMM pulled off its active regenerations by injecting fuel on the exhaust stroke, which inevitably led to cylinder washing and fuel dilution. GM would add a ninth injector to the LML in 2011 to eliminate the post injection event. Other emissions-related changes for the LMM included a larger EGR cooler and an electronically controlled intake throttle, intended primarily to keep the engine under load and heat built up within the engine at all times.

A Bigger, Cleaner, More Powerful Cummins

Image may be NSFW.

Clik here to view.

It’s worth noting that for GM and Ford, the time frame from 2007 to 2010 was an “interim” period. While GM was designing the new LML to meet the January 1, 2010 emissions deadline, Ford was hard at work developing the 6.7L Power Stroke, an in-house V8 intended to put Blue Oval back out front. However, Cummins’ 6.7L met the 2010 NOx emissions standard in 2007. Thanks to a larger bore and stroke, Cummins arrived at 408 cubic inches of displacement, boasting the largest engine in the diesel pickup segment at the time. Its Siamese bore block, higher pressure common-rail system and variable geometry turbocharger were major strength and performance improvements over the previous 5.9L mill.

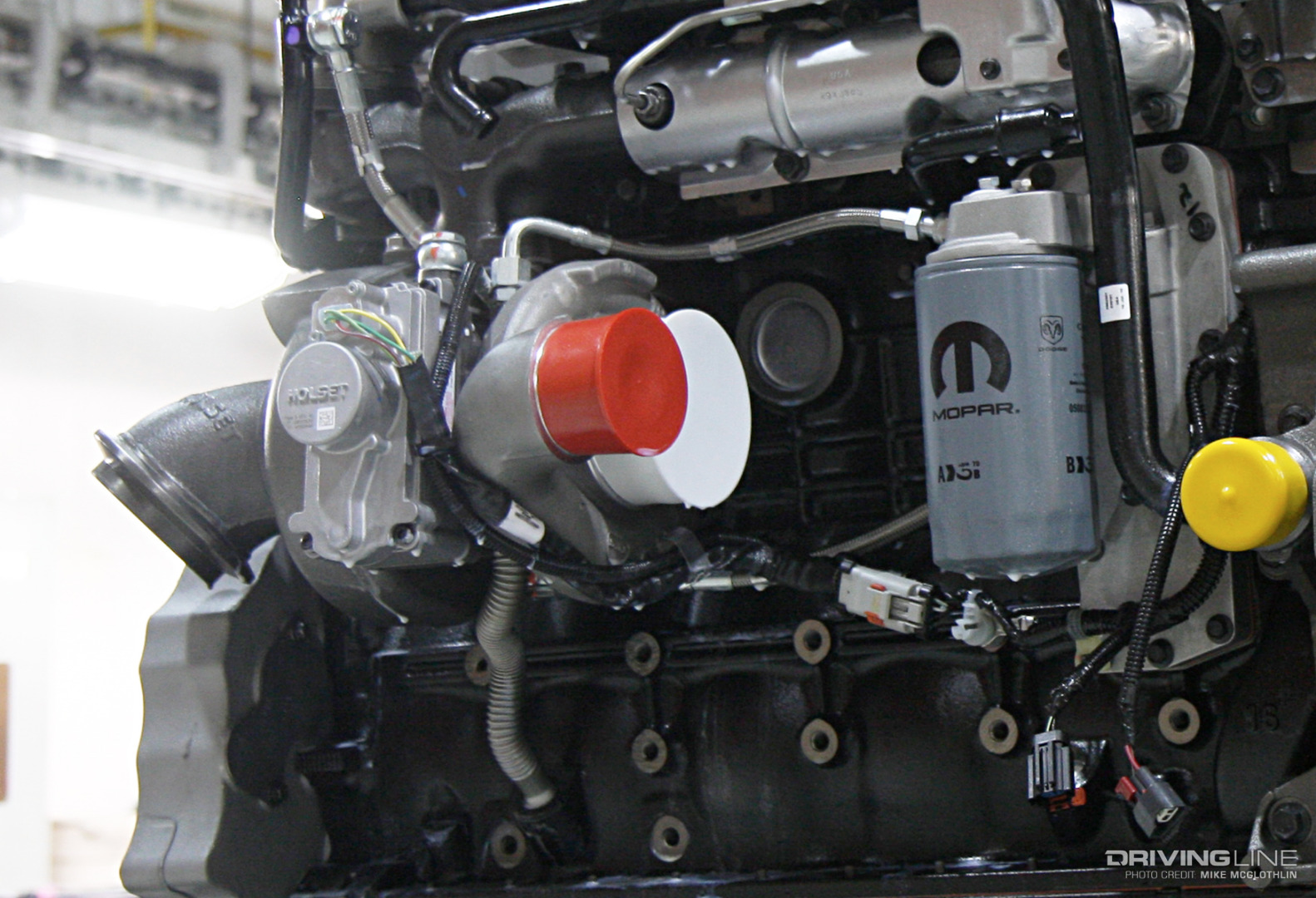

Holset HE351VE

Image may be NSFW.

Clik here to view.

While the instant throttle response it provides is highly welcomed, variable geometry turbocharging is a big part of cleaning up tailpipe emissions (i.e. soot) on diesels. At low engine speeds, the HE351VE VGT aboard the 6.7L Cummins could restrict exhaust flow enough to make the turbo act as if it had a turbine housing as small as a 9cm2. At high rpm, the exhaust flow could be opened up and the turbo made to perform like a unit with a 26cm2 turbine housing. On top of keeping the engine responsive, the HE351VE packed an additional surprise: it featured an integrated exhaust brake that was downright impressive. In the years to come, GM and then Ford would integrate their own exhaust brakes, neither of which were as effective as the HE351VE’s.

Second-Generation Common-Rail System

Image may be NSFW.

Clik here to view.

Just as GM had done with the LBZ Duramax in ’06, the Bosch common-rail injection system on the 6.7L Cummins was revised to support 26,000 psi (vs. 23,200 psi on the 5.9L). Along with the higher injection pressures, a 50-percent larger rail, rail feed lines, injector lines and crossover tubes made the cut. Bosch solenoid valve style injectors were still used, although the 6.7L versions required less voltage to operate.

Six-Speed Auto Option

Image may be NSFW.

Clik here to view.

Crawling out from under the banded, three and four speed automatics of yesteryear (A727, 46RH, 47RH, 47RE and 48RE), Chrysler came up with a modern age six-speed transmission to place behind the 6.7L Cummins. Called the 68RFE, it was completely electronically controlled and featured real-time, adaptive shift and pressure control. The Mercedes-Benz G56 six-speed manual was still an option, but it coincided with the Cummins coming with a lower, 610 lb-ft torque rating.

Curious if the 6.7L Cummins was really better than the 5.9L it replaced? Check out this head-to-head comparison and decide for yourself.