The 7.3L Power Stroke is a widely renowned engine that’s known to last half a million miles if properly looked after, but was it the most reliable Power Stroke ever assembled? We think so, and we think it’s pretty easy to illustrate why. More than a quarter century after the first one was produced you can still find thousands of 7.3Ls working the fields, highways and construction sites every day, not to mention the fact that aftermarket support for the 444 ci V8 is still abuzz with activity.

Sure they lacked the horsepower and torque the modern 450hp and 1,000 lb-ft behemoths do, but it was a different time and the 7.3L’s conservative power rating, combined with its rather simple design, culminated in an engine that’s extremely hard to kill. Below, we’ve narrowed things down to the top nine reasons the 7.3L is the most durable V8 to ever don the Power Stroke name. Have a different opinion? Let us know in the comments or enter the verbal fray on Facebook!

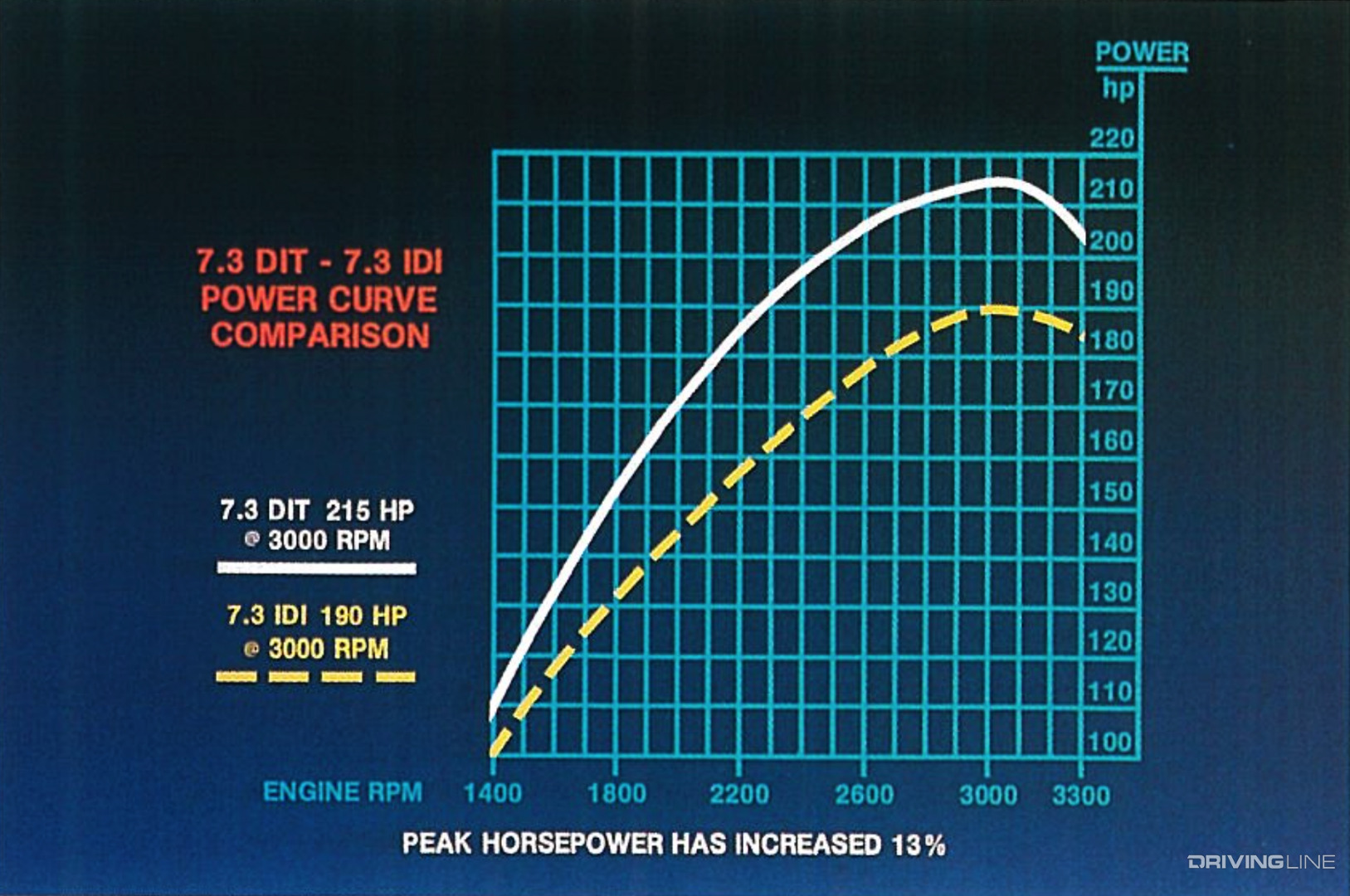

1. Not Enough Power to Hurt Itself

Some of you may find this reason laughable, but if you’ve ever driven a bone-stock 7.3L-equipped ’94.5-’03 Ford you know the struggle that is keeping up with modern day traffic. When the 7.3L debuted in mid-’94, it was rated at 210hp and 425 lb-ft of torque in Power Stroke form (the version of the 7.3L that Navistar built for International trucks was coined the T444E and came with different yet similarly-mild power ratings). While that kind of power matched or beat what Dodge and GM were offering at the time, you were still looking at 0-60-mph times of 14 seconds empty. Robust, iron parts, conservative power and low engine speed are the key ingredients for any diesel engine lasting forever—and if a 7.3L has gone unmodified yet been well maintained its entire life, 400,000 to 500,000 miles is virtually guaranteed.

2. Lack of Emissions Controls = Superb Reliability

A big reason why the 7.3L Power Stroke lasts so long boils down to the absence of emissions controls present on the engine. Aside from the use of a catalytic converter down stream in the exhaust system, the 7.3L’s sole means of meeting emissions regulations relied on the engine’s computer calibration to ensure the engine adhered to NOx standards. By comparison, the exhaust gas recirculation (EGR) system that had to be employed on its successor, the 6.0L Power Stroke, led to a myriad of operational problems (stuck EGR valve, cracked EGR cooler, contaminated engine oil, harder on coolant, etc.). Then, the addition of a diesel particulate filter (DPF) on top of EGR on the 6.4L Power Stroke virtually guaranteed you would never see high mileage.

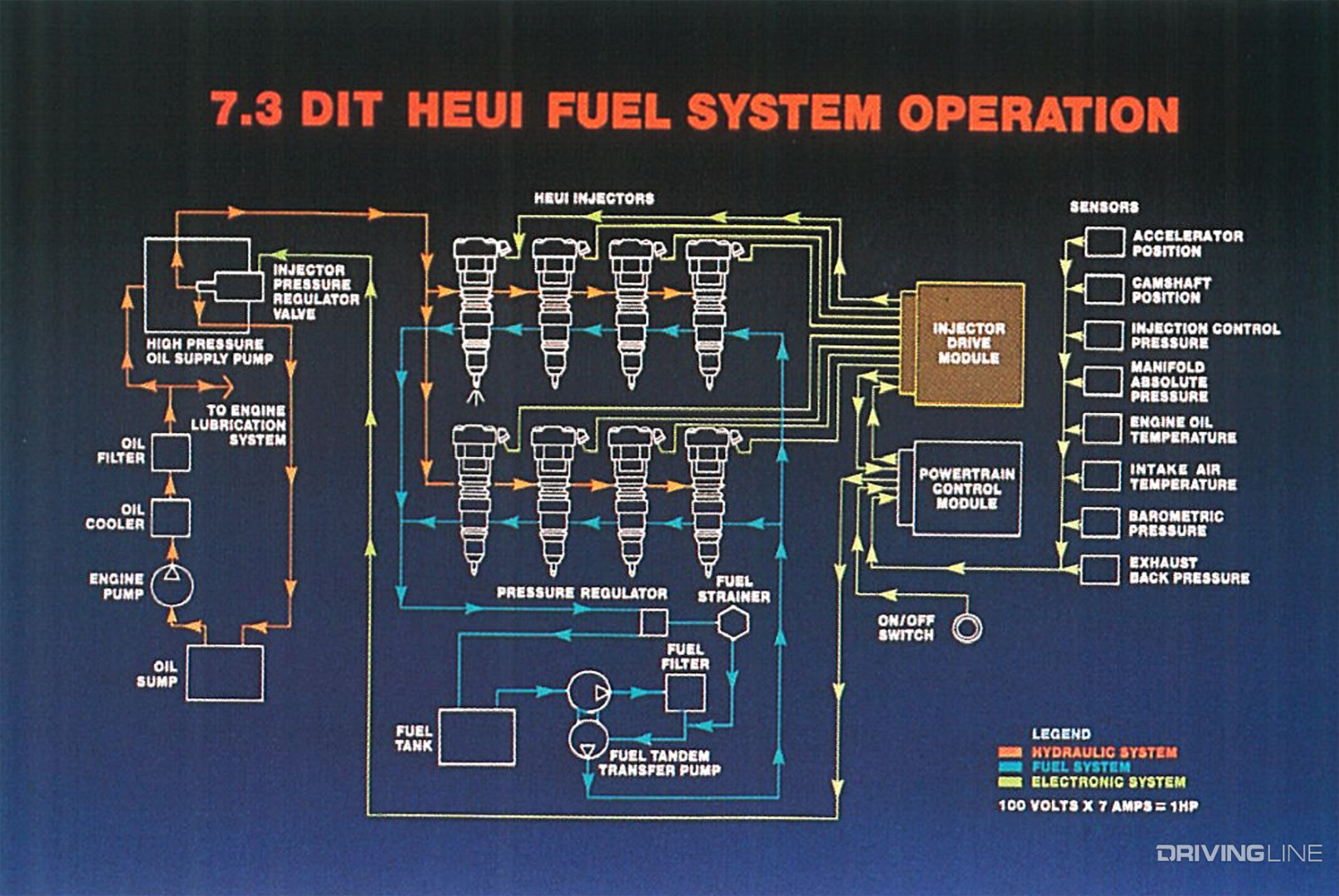

3. Complex Yet Durable Fuel Injection System

Though a bit labyrinthine, the oil-activated fuel injection system used on the 7.3L Power Stroke is extremely reliable if properly maintained. The Caterpillar-sourced HEUI injection system had undergone extensive R&D before CAT leased the technology to Navistar for use on the 7.3L (as well as Navistar’s T444E, DT466E and I530E models). The HEUI system (short for hydraulically actuated, electronically controlled, unit injector) on the 7.3L revolves around a high-pressure oil pump sending oil volume through oil rails integrated into the engine’s cylinder heads, which allows oil to feed the topside of each injector. From there, the pressurized oil acts on an intensifier piston, compressing the fuel below it and resulting in injection pressures as high as 21,000 psi in-cylinder. CAT would also make use of HEUI technology on several of its own engines (some of which were the 3126, C7 and C9), all of which saw good success in terms of durability.

4. Long-Lasting Injectors

The HEUI injectors used in the 7.3L Power Stroke, though fairly complicated to the novice, are quite simple in terms of their fuel injection functionality. Single-shot operation means that—unlike the common-rail injectors used today, which can conduct five or more injection events per combustion cycle—the injectors aren’t as prone to wear. Even when split-shot injectors were introduced on the 7.3L (’97 model year California models and ’99 model year federal engines), a pre (pilot) injection event prior to the main event was made possible mechanically, so the plunger still only operated once per combustion event. Properly maintained 7.3L injectors are virtually guaranteed to go 200,000 miles between overhauls, with most lasting well beyond that.

5. They Keep Their Cool

Even though early 7.3L Power Strokes didn’t come with intercoolers, the ’94.5-’97 engines were able to manage exhaust gas temperature relatively well thanks to their conservative horsepower and torque ratings. Beginning in ’99, EGT was even more manageable thanks to the addition of an air-to-air intercooler. Even with aggressive aftermarket tuning in the mix (and the fact that the ’99-’03 engines came with considerably larger injectors from the factory), it takes a lot of work to get the pyrometer past 1,200 degrees F on a 7.3L-equipped Super Duty. In any turbocharged application, an intercooler undoubtedly makes life easier for both the engine and the turbocharger, and things were no different in the ’99-’03 7.3L’s case.

6. 6 Bolts Per Cylinder

Adding to the 7.3L’s commercial-grade attributes is its use of six head bolts per cylinder, something Navistar got away from on the 6.0L and 6.4L Power Strokes but that Ford reverted back to with its 6.7L in 2011. An untouched (or slightly modded) 7.3L can go its entire life with zero head gasket issues. Even modified versions will run for years or decades without lifting a head. We know of several 7.3L Super Dutys making 375-400rwhp (twice the factory amount) that survived more than 330,000 miles of heavy tow duty (well over GCWR) before popping a head gasket. Had these engines been fitted with head studs (a popular addition in the aftermarket, which makes the stock 7.3L head gaskets capable of living at up to 75 psi of boost), the failure likely wouldn’t have occurred at all. While the generally accepted threshold for boost on a 7.3L’s stock head bolts is 35 to 40 psi, you can get away with close to 50 psi for a while.

7. Simple Engine Design

Virtually nothing is exotic about the large bore, 7.3L V8. Its block is cast from gray iron, the crankshaft is made from forged-steel, the rods from forged-steel (although select ’00 and most ’01-’03 mills came with powdered-metal units) and the pistons from cast-aluminum. The engine’s lone camshaft resides in the traditional, overhead V8 engine location within the block. Like the crankcase, the cylinder heads were cast from gray iron and feature two valves and two pushrods per cylinder. Highly forgiving, hydraulic lifters actuate the intake and exhaust valves, while eliminating the need for periodic adjustments.

8. Fixed Geometry Turbo

A fixed geometry, journal bearing turbocharger kept the forced induction side of the 7.3L simple as well. The most uncomplicated of the lot would be the non-wastegated Garrett TP38 charger that graced the ’94.5-’97 engines (pictured above). Instead of being equipped with a wastegate, the exhaust side was opened up courtesy of a 1.15 A/R turbine housing (which helped keep EGT in check as they were non-intercooled engines). A wastegated version of the TP38 would be employed on early ’99 engines (and with a much tighter 0.84 A/R turbine housing), while a GTP38 model, complete with a larger wastegate and looser 1.0 A/R turbine housing, came on all ’99.5-’03 7.3Ls. In direct comparison, the VGTs that followed would prove fairly problematic on the 6.0L, the 6.4L and even the early versions (’11-‘14) of the acclaimed 6.7L Power Stroke.

9. Externally-Located Oil Cooler

It’s no secret that the engine oil in the 7.3L Power Stroke gets worked hard. In addition to the 20-60 psi of oil pressure being used to lubricate the engine, the oil in the high-pressure circuit gets pressurized to more than 3,000 psi. This builds tremendous heat extremely fast. Luckily, the externally-located oil cooler on the 7.3L is up to the task. In addition to its location exposing it to the cooling effects of outside air, its large internal passageways never plug up. In direct contrast, the oil cooler integrated into the lifter valley of the 6.0L and 6.4L Power Strokes is constantly exposed to excessive heat and features minuscule internal passageways that are prone to clogging and restricting coolant flow to other vital engine components. The only type of failure associated with a 7.3L oil cooler pertains to the seals on both ends, which can leak with age.