Like much of the Midwest, truck pulling is pretty big in Wisconsin. In the summer months, it’s possible to take in a pull every other night of the week up here. For Sun Prairie resident Ryan Sokolowski, he spent the 2018 season campaigning a Pro Stock diesel truck in the Badger State Tractor Pullers circuit. His ’03 Dodge Ram strung together more than half a dozen third and fourth place hooks in a very competitive class, rarely finishing outside of the top five. Ryan also traveled to select Pro Pulling League events, where—still adhering to Badger State’s D.O.T. tire rule—he ran neck-and-neck with some of the strongest-running, cut-tire trucks in the nation.

What exactly is this Cummins-powered, open driveline, mud terrain-equipped Ram’s recipe for success? From its Scheid-built, deck-plated inline-six, to its Pro Fab transmission and transfer case to the six Mud Grapplers tasked with digging it to the front, we’ll highlight the bits and pieces that make Ryan’s Dodge a formidable contender in the Pro Stock field. Your 1,900hp tutorial begins right now.

Greased Up and Ready to Go

When Ryan Sokolowski picked up his 2003 Dodge Ram 3500 prior to the 2018 pulling season, it had already been built to compete in his local, 7,800-pound Pro Stock diesel truck class, sanctioned by the Badger State Tractor Pullers. Aside from a few changes here and there, the third-gen Ram was all but ready to compete. One change would be the renaming of the truck from Smokin’ Black Ram to “All Greased Up,” a label that stems from the line of work Ryan is in: liquid waste recycling.

Scheid Pro Stock Engine

Based on a 6.7L Cummins block and utilizing a 12-valve cylinder head, the dry sumped 6.4L Pro Stock mill in Ryan’s Dodge was built by Scheid Diesel. The Siamese bore crankcase was sleeved, its water jackets filled with concrete and a deck-plate was added to reinforce the upper section of the block. A main bearing girdle, 14mm main studs, billet-roller camshaft, billet rods and 12:1 compression pistons were also incorporated into the bottom end. Inheriting the engine with a full year’s worth of passes already on it in 2017, Ryan’s faith in the Scheid-built Cummins dissuaded him from freshening things up for 2018. Ryan’s gamble paid off, as he got all but a complete second season out of the battle-proven engine combination.

14mm P-Pump

Big power calls for big fuel, and Ryan’s Cummins has plenty of both. Bolted to a Scheid billet front cover, you’ll find one of Scheid’s P8600 P-pumps. Making use of 14mm plungers and barrels, a quick-rate cam and an Ag governor, this pump can flow as much as 1,000 cc worth of fuel and keep fueling well beyond 5,000 rpm. After being fed more than 80 psi of fuel supply pressure via a belt-driven lift pump, the 14mm P8600 sends fuel to six triple-feed injectors, each fitted with a massive, 5x0.030 nozzle.

War Head

Like many other Pro Stock engines—and because billet cylinder heads are prohibited in the Pro Stock class—Ryan’s Cummins benefits from a cast replica head from Hamilton Cams, coined the War Head. With the right port and valve work, the cast-iron 12-valve piece can be made to flow twice what a restrictive factory 12-valve head can. Ryan’s War Head anchors to the 6.7L block via 14mm ARP studs and accommodates an individual runner-type intake manifold from Scheid.

Single, 3.6-Inch Turbo

In both Pro Stock and Limited Pro Stock diesel truck classes, you’ll find that most rigs are equipped with a turbocharger from Hart’s Diesel. In the Pro Stock field, engines are limited to running a single, smooth bore turbo with a compressor wheel inducer that measures no more than 3.6 inches in diameter (91.5mm). The Hart’s 3.6-inch charger on Ryan’s engine produces as much as 70 psi of boost during the heat of a pull, with drive pressure that checks in close to the same.

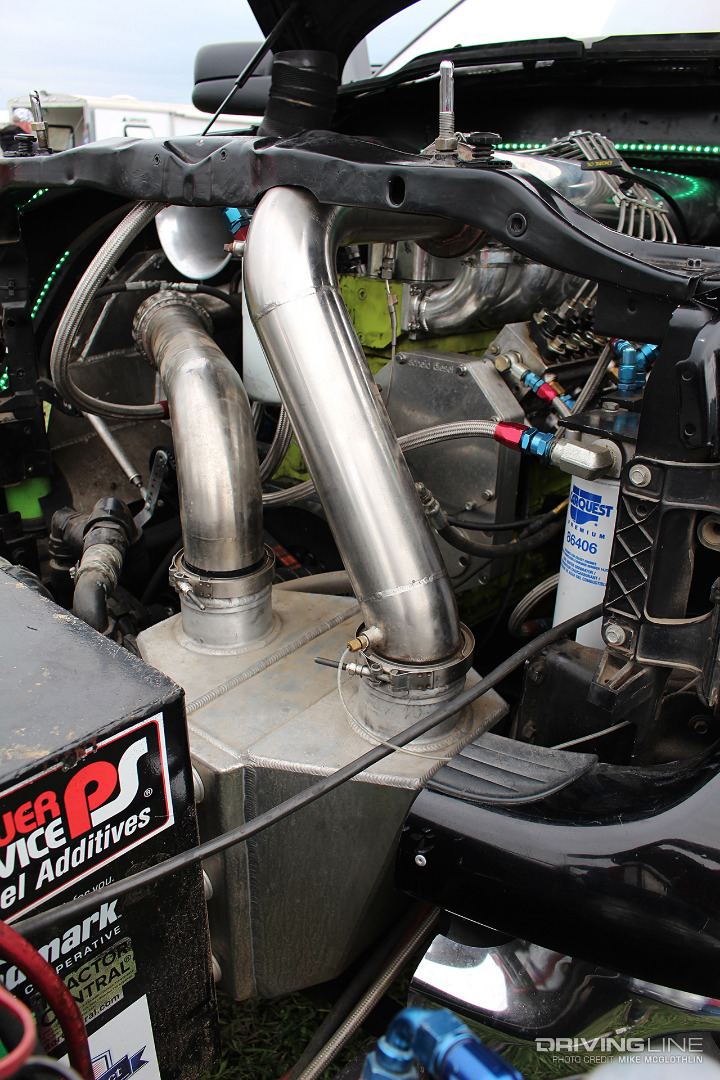

Ice-Cold Intake Air

As you can imagine, air that’s been compressed to 70 psi can heat up in a hurry, so much so that the charged air leaving the turbo’s compressor housing tops 500 degrees F in Ryan’s case. To cool incoming air down before it makes it into the high-flow head, it passes through a water-to-air intercooler arrangement. Thanks to a shaft-driven pump, nearly 120 pounds of ice and the multi-core intercooler itself, air temps entering the engine check in at a cool 60 to 70 degrees F. As for EGT, those temps remain a calm 1,300 to 1,400 degrees (per cylinder) most of the time.

Open Driveline

The process of transferring as much of the 1,800+ hp produced by the engine to the wheels begins with a four-disc Crower clutch inside a Browell blow-proof bellhousing. From there, power makes its way through a one-speed reverser transmission from Pro Fab Machine. Finally, a Pro Fab quick-change transfer case, located aft of the driver seat, routes power to the front and rear axles.

Indestructible Axle

You’ll find the rear axle pictured above in most serious pulling trucks these days: the Meritor/Rockwell 20-145. Sourced as a complete unit from Proformance Pros, the dual wheeled 20-145 benefits from 2-1/16-inch, 32-spline, gun-drilled (lightened) axle shafts made of 300M, a new axle drive flange and a billet spool. Up front, an AAM 1150 was repurposed as a front axle and equipped with hydraulic steering and a Detroit Truetrac.

Front Suspension Only

With solid suspension out back (to keep the rear end as rigid as possible and ensure the hitch height never drops), only the front suspension can be altered. To dial in the front end’s behavior, two adjustable AFCO coilover shocks are utilized on each side of the AAM 1150 axle. According to Ryan, now that the truck seems to be in its happy place on most tracks, the AFCOs rarely require adjustment. Also notice the steel deflection shield behind the shock mount in the photo shown above.

Mud Grapplers: The Path to the Front

While many sanctioning bodies allow bar tires on Pro Stock diesel trucks, cuts remain prohibited within the ranks of the Badger State Tractor Pullers’ Pro Stock class. But after speaking with several Badger State competitors, they don’t seem to mind running a street-legal tire. After all, they’ve already picked a winning horse. One thing about the BSTP Pro Stock category is certain: as long as D.O.T.-approved tires are the order of the day, competitors will choose Mud Grapplers. All six LT315/75R16 Mud Grapplers aboard Ryan’s Dodge reside on 16x10-inch aluminum Real Racing wheels.

The Careful Application of Power

At nearly 1,900hp, it’s pretty easy to overpower a pulling track, which is why a typical pull for the All Greased Up Dodge includes walking the truck off the starting line (a sophisticated way of saying “slip the clutch”) so as to avoid blowing the tires off. With the truck rolling and once Ryan feels the truck “dig in,” he gradually yet quickly moves the hand-throttle forward. By roughly mid-track, it’s full steam ahead. That means 4,300 rpm, 70 psi of boost and 30 mph worth of ground speed with 20 tons of weight-transferring iron in tow. Then once the sled drags things to a halt the truck spins out—and Ryan hopes his distance was enough to beat everyone else’s.