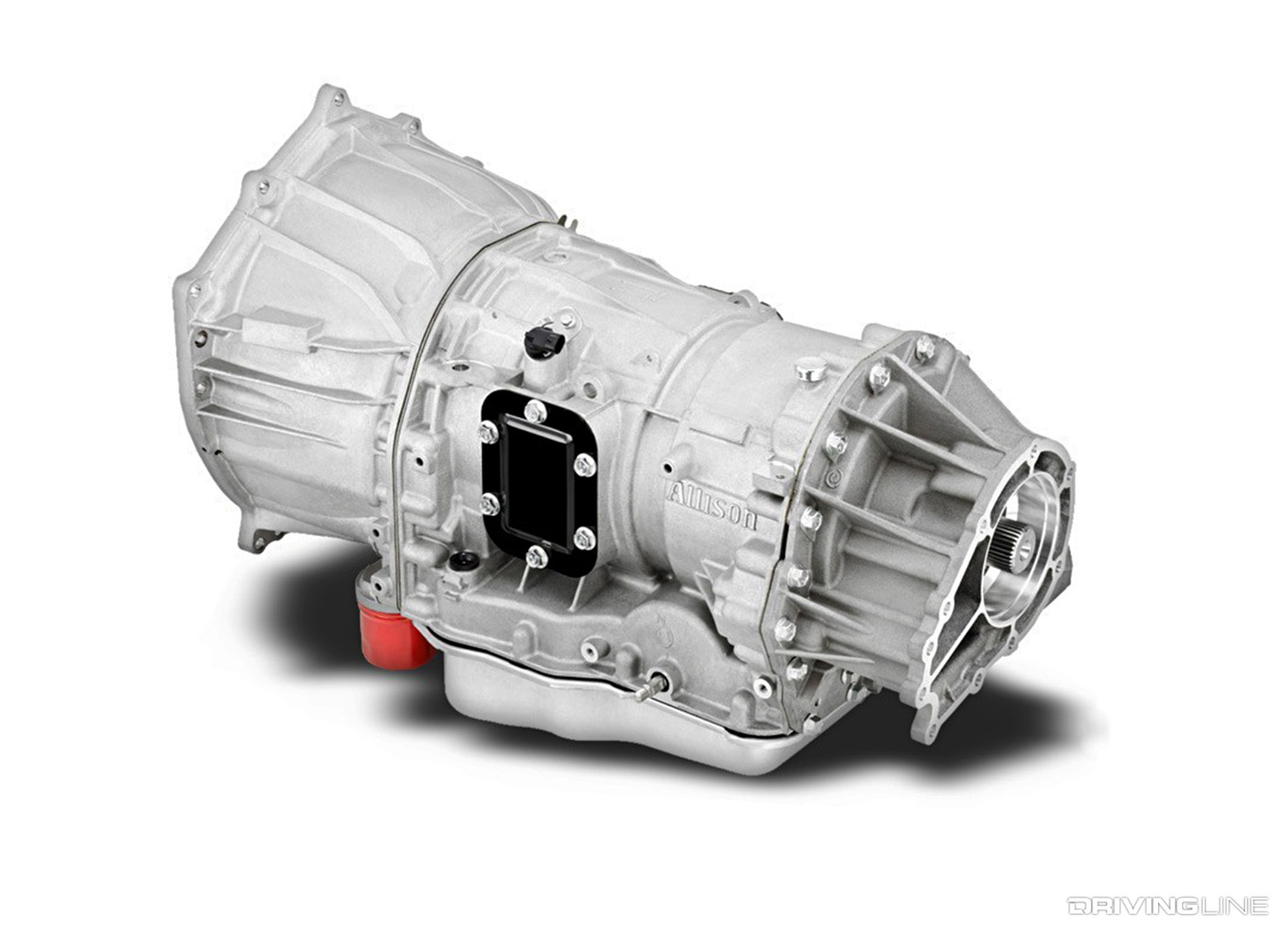

Without question, the Allison LCT 1000 brought medium-duty robustness to GM’s heavy-duty truck line, along with adaptive learning, shift energy management and some of the burliest components you’ll find inside an automatic transmission. To say the Allison revolutionized the heavy-duty pickup segment would be an understatement. It was also a sign of things to come, as a call for increased power ratings, better fuel efficiency and more stringent emissions standards were on the horizon and would have to be met with stronger, smarter transmissions.

When the clutch-to-clutch Allison 1000 debuted in GM trucks back around the turn of the century, it was both brand new and highly advanced in terms of what the competition was offering. After all, Ford’s 4R100 was a rendition of the E4OD, which was based off of the old C6—and Dodge’s 47RE was hardly an improvement over the 47RH, A518 and 727 that came before it. What do we mean by clutch-to-clutch? It means no sprags, bands, or overrunning clutches exist within the transmission. Instead, its clutch packs are applied (and unapplied) in precisely timed intervals, which come courtesy of a highly intelligent, transmission control module (TCM).

If the Duramax is left unmodified and the Allison properly maintained, owners can expect the transmission to outlast the durable 6.6L V8 it’s bolted to. However, most Duramax/Allison owners don’t leave their trucks stock—and therein lies the problem. Aftermarket ECM tuning with little or no attention paid to the importance of TCM tuning can kill or limp an Allison in short order. And while no two transmissions are exactly alike, an extra (and easily achieved) 80 to 100 horsepower can toast a five-speed version, while an added 120 hp can destroy the six-speed units. Follow along as we spell out the weak points of each version of the Allison and how you can keep yours alive for the long haul.

1. Allison 1000, Five-Speed (’01-’05)

Of a modular design, the Allison 1000 consists of three major sections: the front cover (i.e. bell housing), main case (which houses the geartrain, PTO gear, if applicable, and valve body) and rear cover (tail housing). An external, spin-on filter greatly simplifies the servicing procedure (the internal filter only requires replacement in the event of an overhaul) and a large, 1.26-inch diameter input shaft lends itself to a high input torque capacity. As far as the diesel aftermarket is concerned, the original five-speed Allison (found behind both LB7 and LLY Duramax-powered Chevy and GMC HD’s) was the weakest version offered. These first generation units will cope with an extra 80 to 100 hp over the factory power rating, but go much beyond that and you’re asking for trouble.

Boiling Point: 340 to 400-rwhp

One of the biggest weak links in the five-speed Allison lies in the C1 and C2 clutches. Due to off-center apply pistons, uneven pressure is applied to these clutch packs once they’re engaged. Essentially, only 50-percent of the C1 and C2 clutches’ holding strength can be utilized. And as such, when the C1’s and C2’s are shot, they only appear to be half-worn.

2. Allison 1000, Six-Speed (’06-’07)

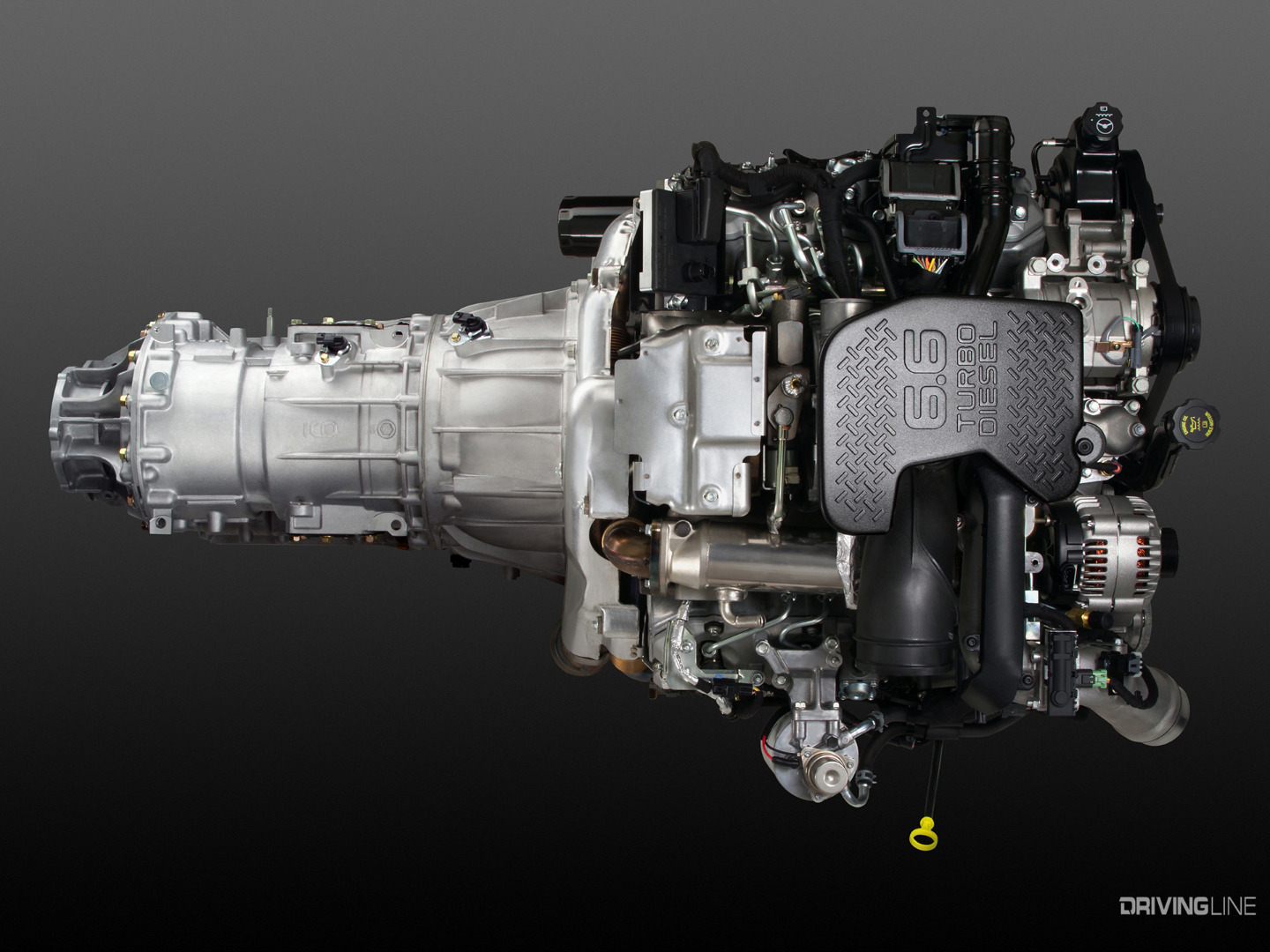

The Duramax/Allison combo is arguably one of the best powertrain duos in the 35-year history of diesel pickups. The partnership pictured above shows the highly sought after LBZ code Duramax mated to a six-speed Allison 1000. The LBZ-equipped GMs would be the first trucks graced with the six-speed, which began in the ’06 model year. This version added a double overdrive gear with an MPG-friendly 0.61:1 ratio and a better designed C1/C2 clutch pack arrangement to rule out the aforementioned (and premature) C1/C2 failures.

Boiling Point: 425 to 450-rwhp

While the failure-prone, C1 and C2 clutch pack situation was rectified with the release of the six-speed Allison, nothing was done to better preserve the life of its hardest-working clutch pack: the C3 clutches. To this day, the C3’s remain the most common clutch to fail in the Allison 1000. One reason is because the C3 clutch pack only receives lubrication when it is being applied. The absence of regularly circulated ATF tends to burn up the clutch plates’ inside edges. A great remedy for this lack of lubrication problem is the billet PTO covers designed by Goerend Transmission. The aftermarket covers incorporate internal fins that route fluid directly to the C3 clutches at all times (even when the C3’s aren’t being applied).

3. Allison 1000, Six-Speed (’07.5-’10)

Although little changed between the six-speed Allison used on ’07 and ’07.5 trucks (LBZ and LMM Duramax’s, respectively), we’ve found that the version employed behind the ’07.5-’10 trucks holds up slightly better in stock form to higher horsepower. By the time the LMM-powered GMs hit the market, aftermarket tuning of the TCM had progressed enough to where the Allison could withstand 430 to 450-rwhp for extended periods of time—and 500-rwhp on occasion.

Boiling Point: 450 to 500-rwhp

Regardless of whether or not the six-speed Allison used behind the LMM Duramax was stronger than the version employed behind the LBZ, the torque converter remained a key weak link once added power was introduced. As some of you know, once a converter goes south in an automatic transmission it contaminates the fluid, which almost always trashes the rest of the transmission. Complete performance transmission rebuilds typically start around $5,000 for the Allison—no small chunk of change—so in order to get around the converter problem without breaking the bank, many budget-minded owners become proactive. With a better (aftermarket) converter, valve body work and good tuning in the mix, you can usually get away with making 500-rwhp or more for years (provided you drive sensibly).

4. Allison 1000, Six-Speed (’11-’16)

Thanks to the LML Duramax being offered with 765 lb-ft of torque in stock form, the Allison 1000 had to be upgraded for the ’11 model year. Among the OEM changes included a different torque converter, low-drag clutch packs and a new TCM. While the torque converter and C3 clutches were still the first weak links to be found, we did witness one stock Allison hold up to more than 600-rwhp. However, the numbers were made on a chassis dyno and with the transmission held in one gear (much easier than making 0-to-100 mph runs and allowing the transmission to shift through the gears). There is no way to tell how long an Allison will live at that power level—and the owner certainly didn’t wait around to find out. He immediately treated the transmission to a full-on build for peace of mind.

For the first time, the TCM was also (electronically) in charge of main line pressure on the ’11 Allison. To reduce internal temperature, the main line pressure is reduced to as little as 80 psi during instances of steady-state driving. This is fine for stock trucks, but once aftermarket tuning cranks up power output, considerably higher pressures are needed (250 psi or more) in order to keep the clutches from slipping and damage from occurring. For quite a while, the aftermarket was in a pinch without having the capability to tune the ’11+ TCM, but now that TCM tuning is available a lot of trucks are living in the 500-rwhp range.

Boiling Point: 475 to 525-rwhp

“Limp Mode”

Many diesel enthusiasts and even layman have heard the term limp mode associated with the Allison transmission. But, what exactly is it? It’s the electronic side of the transmission sensing excessive slipping and placing the unit in fail-safe mode, where only one forward gear is available. As you’ve probably deduced up to this point, the stock Allison will handle roughly 350 to 400-rwhp in five-speed form and 425 to 450-rwhp in six-speed trim. However, if you push things past that point the clutches will eventually slip and bring on the Allison’s notorious “limp mode” condition (i.e. limp home mode). During limp mode, maximum line pressure is commanded, no voltage is sent to the transmission and you’re stuck in Third gear. Just as its technical name implies, it allows you to limp the truck home. While many owners continue to drive their trucks after a limp mode scenario has occurred, subsequent limps will eventually ruin the transmission. If you limp yours, we suggest preparing for a performance rebuild or backing down the programmer.