If you own a ’98.5-’02 Dodge Ram 2500 or 3500 powered by the 24-valve version of Cummins’ 5.9L inline-six diesel, chances are you’ve suffered a failed injection pump, replaced a lift pump or even experienced an ECM gremlin or two. Chances are also good that your old Dodge struggles to keep up with newer trucks, even though you’ve added more power via programmer, larger injectors or a different turbo.

By now you know that the VP44 injection pump is limited in its high-rpm fueling abilities — that it’s left you stranded in the past (and likely will again) — and you’re ready to throw in the towel. But what if there was a way to improve injection system reliability and add considerable horsepower at the same time? Instead of trading in your old workhorse for a brand new, $70,000 steed with common-rail injection and all the other modern day bells and whistles, there is a relatively inexpensive fix for the 24-valve Cummins’ injection system woes. The solution? A P-pump swap.

That's right — reverting back to the mechanical injection system that made the ’94-’98 Dodge Rams so legendary. For starters, a P-pump (Bosch P7100) adds dependability and hundreds of horsepower to the equation. On top of that, in the case of the ’98.5-’02 trucks, the added fueling and rpm capabilities afforded by the P7100 are combined with the higher flowing 24-valve cylinder head, resulting in vastly improved drivability.

Follow along as we highlight key components required in pulling off a P-pump conversion. This is how you make a 24-valve Cummins worth keeping!

Victim of Circumstance

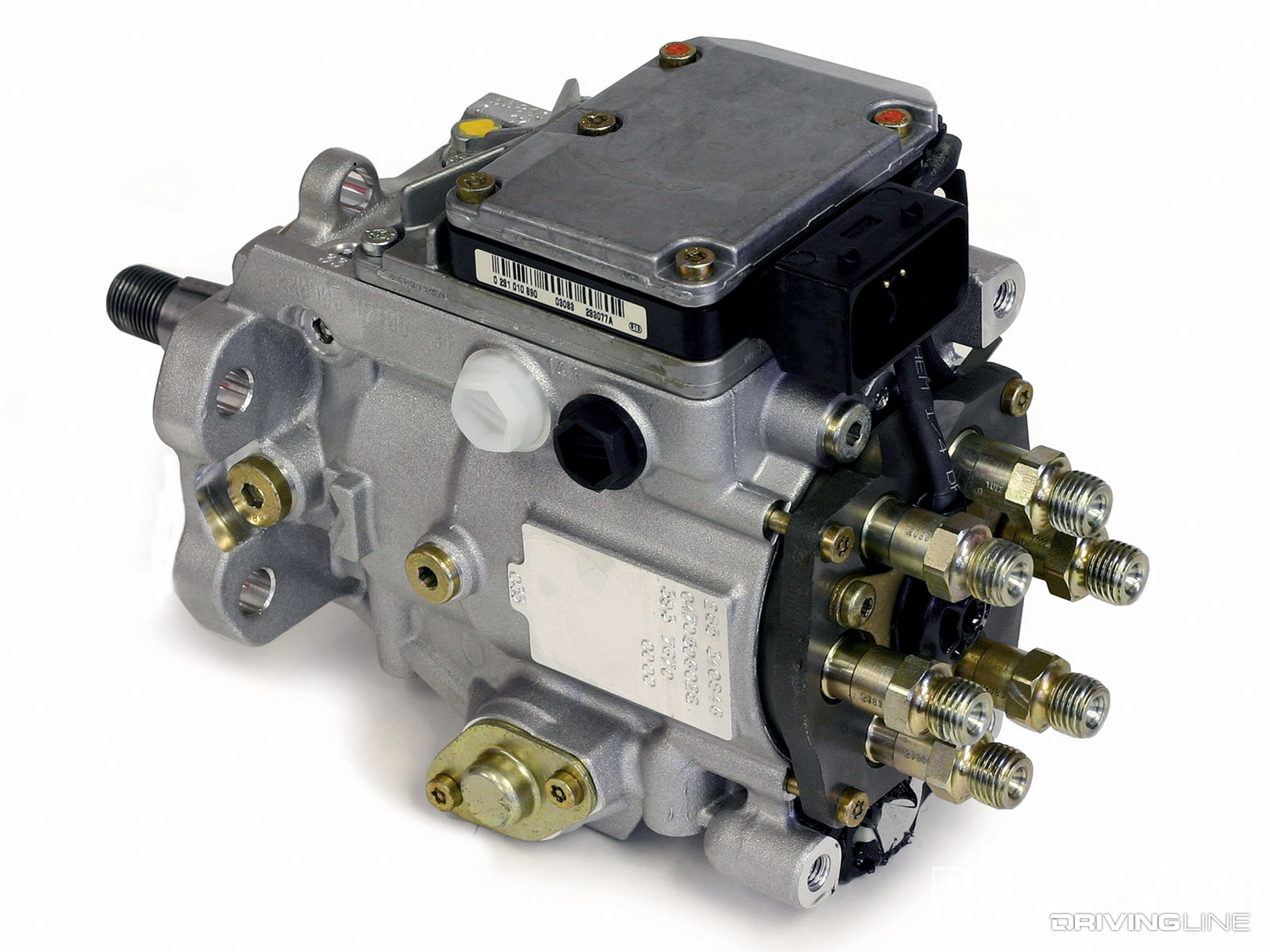

This is a Bosch VP44, the factory injection pump employed on all ’98.5-’02 24-valve 5.9L Cummins engines. It’s an electronically controlled and regulated, distributor-style pump (also known as a rotary type) that was chosen to fuel the 24-valve due to its ability to meet the emissions standards of the late ‘90s. The VP44 is equipped with a computer (EDC) married to the top of it, which monitors and precisely adjusts in-cylinder fueling. Fuel metering is performed independent of engine speed.

Zero psi = Zero Chance of Survival

From a reliability standpoint, the VP44’s Achilles heel is the sub-par lift pump that supplies its lifeblood: diesel fuel. While it’s widely accepted that the VP44 is unreliable, in reality it’s the factory lift pump that’s to blame for its early (100,000 to 150,000-mile) demise. Once the factory lift pump no longer provides adequate fuel supply pressure to the VP44 (and when it sees 0 psi for extended periods of time), the EDC atop the VP44 is exposed to extreme heat and eventually fails.

P-Pump vs. VP44

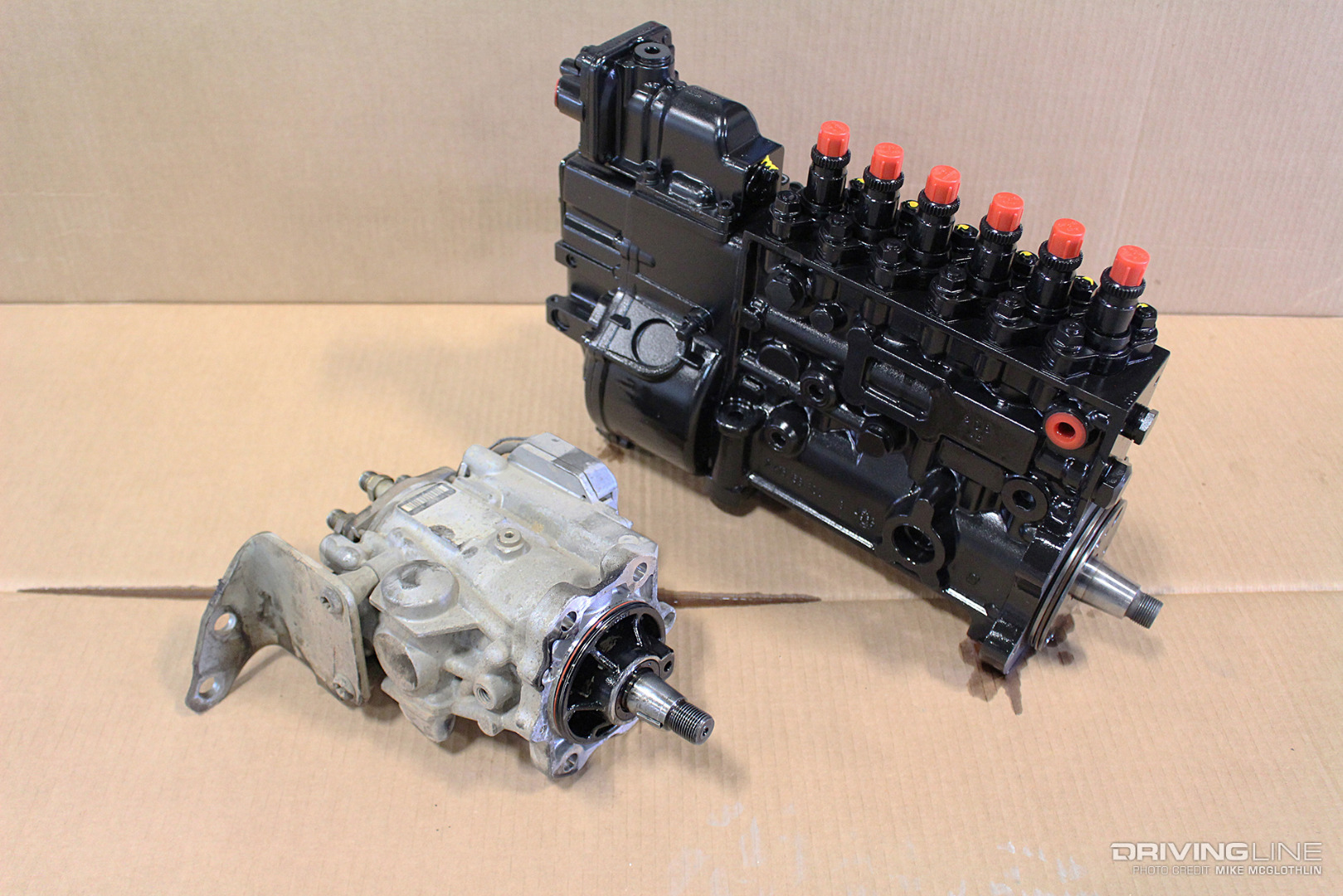

There is no question that the P7100 can outperform the VP44 in every way (fueling, rpm capability, reliability), and the photo above is worth a thousand words (VP44 on the left, P7100 on the right). Even in the case of an extremely modified VP44, roughly 600 cc's worth of fuel volume is on the table. By comparison, a stock (albeit modified) P7100 still utilizing the factory 12 mm plungers and barrels can flow as much as 650 cc’s worth of fuel. Larger plungers and barrels (i.e., 13 mm), a quick-rate cam and a plethora of other internal upgrades can get the P7100 pumps to flow 850 to 950 cc’s — enough fuel to make north of 1,800 horsepower.

Complete Bolt-on Kit

So what’s involved in the P7100 swap? Dozens of different parts, quite a bit of time and a lot of work! Luckily, Scheid Diesel offers complete conversion kits to make the process as seamless as possible. While the P7100 conversion is by no means a cheap proposition (the Scheid kit starts at just under $2,300, less than the pump), the folks interested in performing the swap have either completely had it with the VP44/electronic system or are primarily after making more horsepower with their truck.

Digging In

In order to accommodate the P-pump, a gear housing off a ’94-’98 12-valve engine has to replace the ’98.5-’02 version. The twist is that housings can’t be swapped without first removing the camshaft. This means that everything in front of the engine has to go, which includes the front bumper, radiator, intercooler, fan and fan shroud, even vacuuming down the A/C system. Then once the valve bridges, rocker arms and push tubes have all been pulled, the lifters have to be held in place above the cam while it gets removed and reinstalled. This calls for the use of ½-inch diameter wooden dowels, which grab ahold of the lifters (in pairs), suspending them in place (shown above).

Cam Extraction

Because the cam has to be pulled for a P7100 conversion, some enthusiasts use the project as the perfect opportunity to upgrade to an aftermarket unit. To further capitalize on the higher rpm capability that comes with running a P-pump, many competitors opt for a cam intended to shine at elevated engine speeds (above 4,000 rpm). On a related valve train note — and because P-pumps almost always increase both the amount of boost and rpm an engine sees — it also pays to install stiffer valve springs (if the owner hasn’t already done so) during a P-pump swap. Hamilton Cams is a great source for camshafts, stronger push tubes and upgraded valve springs for the 5.9L (and 6.7L) Cummins mills.

If Time Is Money…

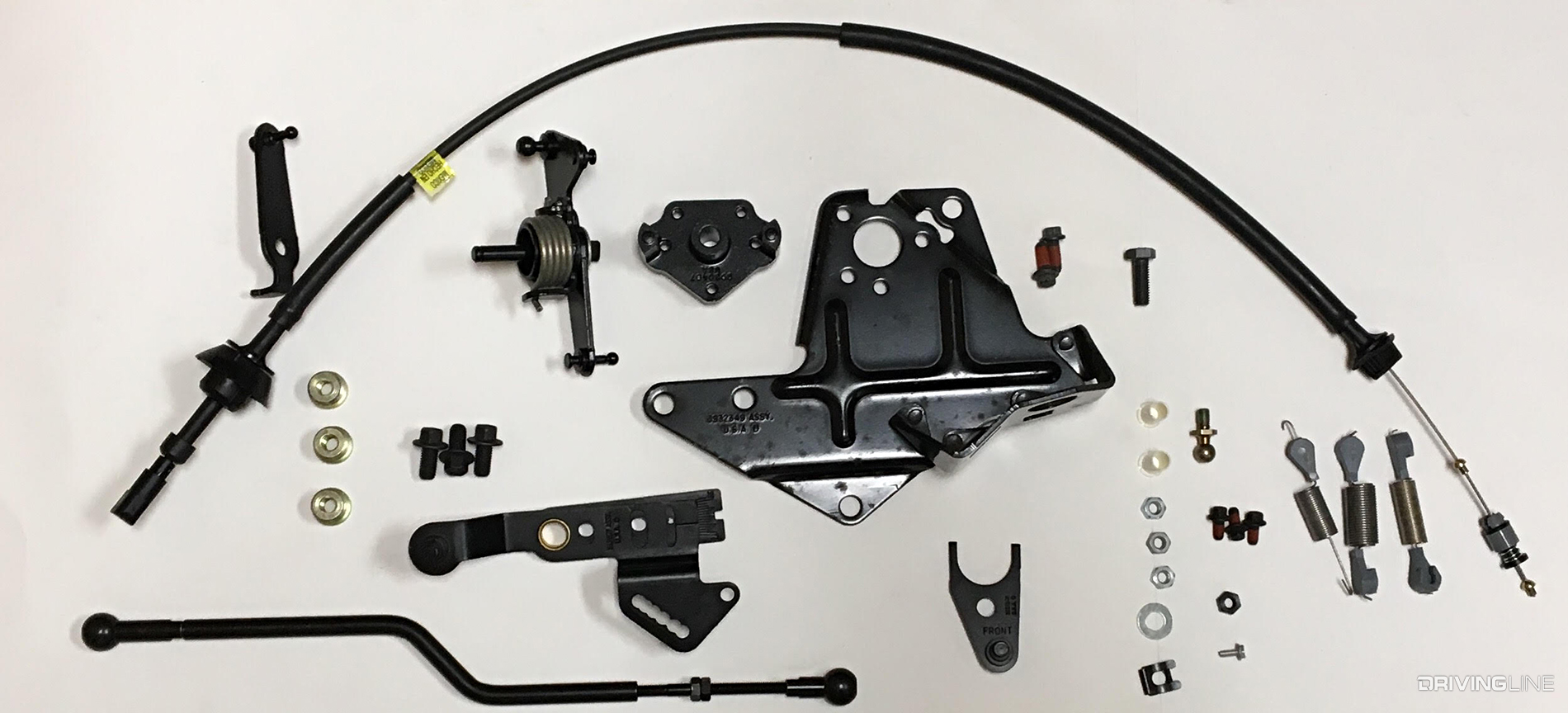

As mentioned, a 12-valve gear housing has to be bolted to the 24-valve Cummins’ block in order to furnish the P7100, but you’ll also need the correct pump drive gear, the appropriate throttle linkage, a cam sensor adapter, P-pump support bracket, P-pump oil feed line and a whole host of other miscellaneous components. As you can imagine, trying to source all of these parts individually could take a while, which makes the all-inclusive kit offered by Scheid all the more appealing.

Mildly Modded = 700 HP Capability

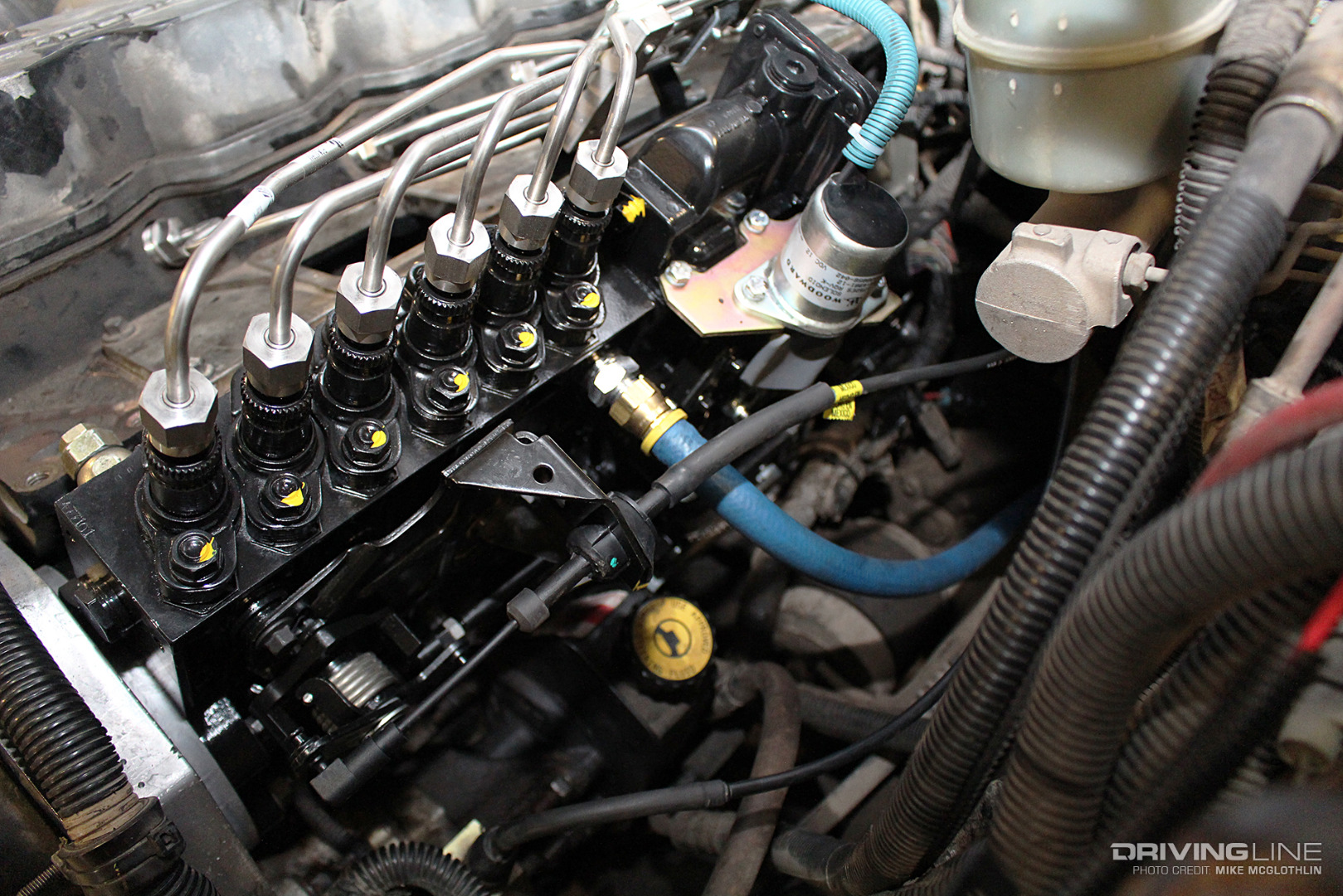

For a street-driven P-pumped 24-valve application (such as the one shown here), even a mildly modified P7100 can net 650-to-700-rwhp with the right turbo. The pump pictured above will do just that, as it’s based on the highly desirable 215hp P7100 model (a pump with a more aggressive cam profile), features 4,000-rpm governor springs, a custom fuel plate and has been set to 18 degrees of timing advance. This pump has also been treated to a fuel shut-off solenoid (bolted to the rear of the pump), which is ideal for daily driven or street use. The shut-off solenoid is in charge of allowing and stopping fuel flow to the P-pump (i.e., what kills the truck when you turn off the ignition).

Different Injection Lines

Because the fuel lines spanning from the injection pump to the fuel injectors are different between a P-pumped Cummins (’94-‘98) and a VP44-equipped version (’98.5-‘02), 12-valve lines are in store. Once again, Scheid Diesel’s P7100 conversion kit saves the day here, and what’s more is that it includes a billet 1-inch thick spacer, which allows the 12-valve lines to clear the ’98.5-’02 intake elbow. Scheid’s stainless steel, 0.093-inch diameter injection lines are shown, which come (pre-clamped, even) with the P7100 conversion package (larger, 0.120-inch lines are optional).

The Missing Link

A reworked throttle linkage is warranted in a P-pump swap as well. This version incorporates the throttle position linkage ball from the 24-valve application into a linkage assembly originally designed for the 12-valve engine. It too is included in the Scheid Diesel P7100 conversion kit.

ECM Relocate

Some novice enthusiasts are surprised to learn that the ’98.5-’02 ECM has to be retained in a P-pump swap. This is because, although it will no longer have anything to do with the injection system, it’s still needed in order for items like oil pressure and water temp sensors to continue to function properly, as well as the gauge cluster. It’s common for the ECM to be relocated further toward the firewall than it was from the factory (due to the immense size of the P7100), although most installers opt to leave the ECM on the driver side of the block.

Up the Pressure

The last item of business is making sure the correct lift pump is being utilized to feed the P-pump. Unlike the VP44, which requires 8-to-10 psi worth of fuel pressure, a P7100 needs to see between 25 and 30 psi at all times, and even more than that if the owner is making big power. FASS and AirDog both make all-inclusive aftermarket fuel supply systems specifically for P-pump applications, which will tack another $700 to $900 onto the overall cost (depending on which system you choose).

500 HP to 700 HP (Night and Day)

So, what’s it like to add a P7100 to a 24-valve Cummins? In this particular truck’s case, it means another 200 hp is on the table. With the VP44 in the mix, the owner was having a hard time cracking the 500-rwhp barrier — even with larger injectors and a bigger turbo feeding the engine. Now with the same injectors and turbo, considerably more boost is on tap, traction can be unheard of (at times) and an estimated 700-rwhp makes it to the ground. Of course, the truck also emits that one-of-a-kind note only a P-pumped 24-valve can produce.