It’s called the snowball effect. You modify one area of your 4x4, and then that modification requires you to modify another part; on it goes until your wallet is empty, and your Jeep is full of awesomeness. The most common modification done to a given 4x4 is installing a suspension lift along with a larger set of tires.

From there, you might add on some small accessories, maybe even a winch bumper and additional body armor. Before you know it, you’ve added some serious pounds to your machine and now it feels sluggish. To get more umpf back into your vehicle, you typically have two options: A) Add more power, or B) Replace the stock differential gears with a numerically higher set. In our experience, swapping out the differential gears is the easier and more cost effective path.

For our 2013 Jeep Wrangler Unlimited Rubicon, we were in the same boat as many Jeep owners. Running 35x12.50R17 Nitto Ridge Grapplers and 3.73 differential gears, our JK’s performance was a little underwhelming, but livable. Post our 5,000-mile round trip to Moab, Utah, from North Carolina, we decided that we’d had enough of the constant downshifting on the highway and sluggish takeoff around town. To start our gear transition, we contacted the premium gear manufacturer Nitro Gear & Axle. Given that Nitro offers a variety of gear packages for the JK, we were able to get exactly what we needed for our application.

Gearing Basics

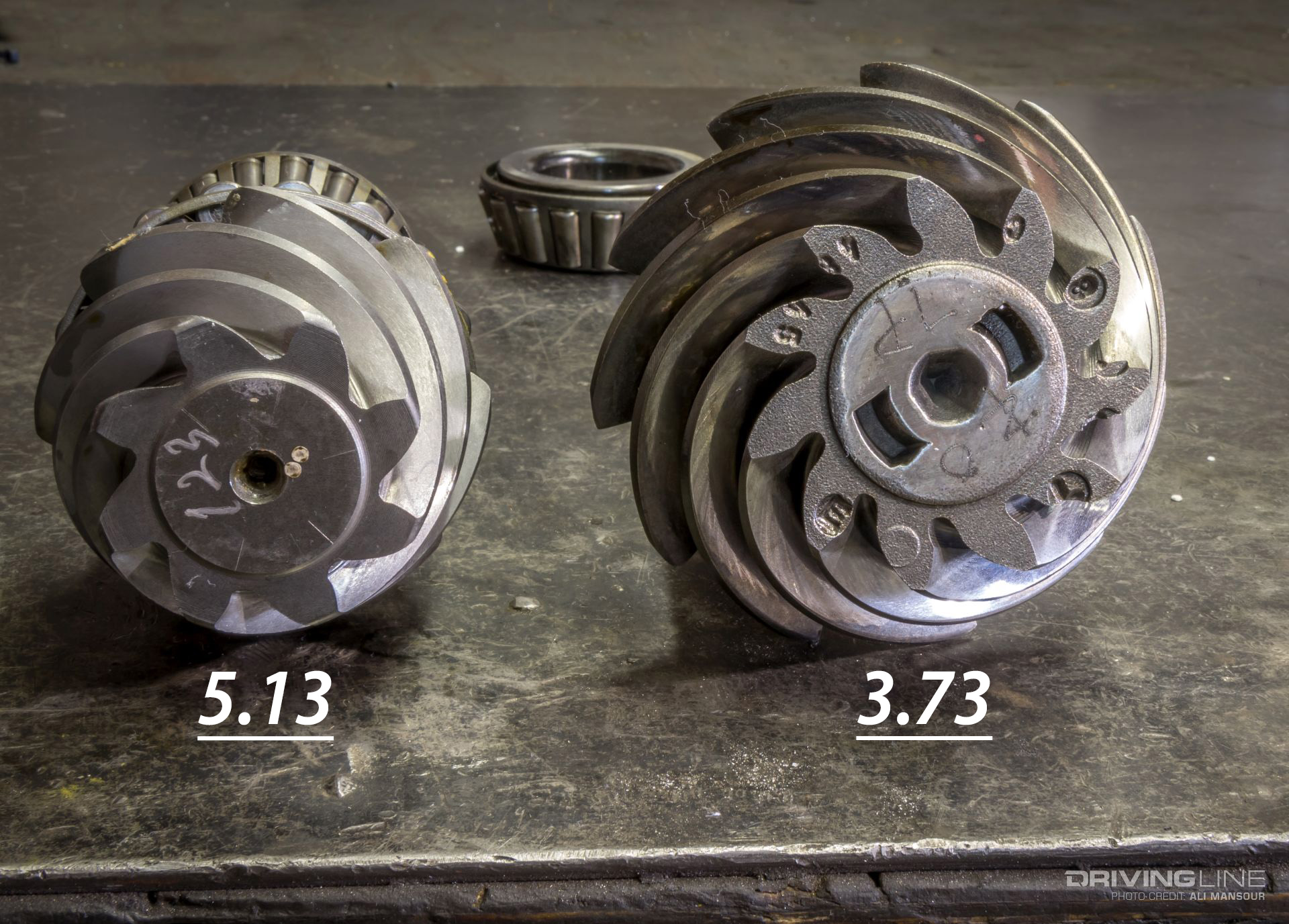

From the factory, our automatic JK came with 3.73 differential gears. While 4.10s were an available option, ours unfortunately didn’t come with the higher numerical gear set. This brings us to commonly misunderstood jargon when talking about gearing. A higher numerical gear ratio such as a 5.13 is often referred to as a lower gear. Don’t get too caught up in this. Just remember, a higher numerical gearset is what’s needed to compensate for a taller tire.

The concept behind moving from a low numerical gear to a higher numerical gear set is all about torque multiplication. By moving from a 3.73:1 ratio to a 5.13:1, the pinion will now turn 5.13 times for every one time the ring gear rotates. This helps reduce strain on the transmission, ultimately allowing the power to be delivered from the engine more efficiently.

Picking the Right Ratio

There are a number of things to consider when picking the right gear ratio for your four-wheel drive. How many gears does your transmission have? What’s your intended use? Rock, sand, mud, the mall — where are you headed? There are also other incredibly important factors to consider such as tire size, engine power, vehicle weight and so on.

Most gear ratio charts will steer you towards getting your vehicles performance and RPMs back to stock. For our Jeep Wrangler JK, stock wasn’t overly impressive, so we wanted to go a little higher numerically to add a bit more getup to the Jeep. This is why we opted for a 5.13. Although, the 5.13 is a bit aggressive for our 35-inch tire diameter, we know that 37s will eventually be under the Jeep. Going with the 5.13 gears now means we will not have to re-gear a second time when we move up tire sizes.

While the engine may rev a bit higher, it’s not drastic nor damaging. The fact that the transmission will be less likely to search or downshift to maintain speed on is worth the extra RPMs. The lower gears also mean high range will be more usable off-road in sand and snow conditions where wheel speed is important.

The Install

We’re pretty hands-on when it comes to building our 4x4s, but even with our years of experience, we tend to leave setting up differential gears to the professionals. For this, we enlisted the help of Low Range 4x4 in Wilmington, North Carolina. While gearing both differentials in a four-wheel drive is an absolute must, in this installment we are focusing solely on our Jeep’s rear axle. Check back soon to see what heavy-duty upgrades we have in store for the front of our Jeep.

In a low-pinion rear axle such as our JK’s Next Generation Dana 44 Rubicon rear housing, the differential takes a standard-rotation Dana 44 gearset. Nitro uses a thick gear for the 8.8-inch-diameter 5.13 ring gear, which allows us to reuse our JK’s stock electronic locker.

When changing differential gears, you’ll need all new bearings for the pinion and carrier. These are sold in what’s commonly known as Master Install Kits. This one from Nitro Axle & Gear included new bearings, shims, pinion seal and ring gear bolts, so we had everything we needed to get the job done.

The first step to breaking down the rear axle is pulling the tires. We’re running 35x12.50R17 Nitto Ridge Grapplers, which are holding up great after 10,000+ miles of use (and some abuse).

The JK’s Dana 44 rear is a semi-float axle. To remove the ‘shaft assembly, you’ll pull the brake calipers and rotors, unbolt the wheel-speed sensor, then remove the four axle-flange mounting bolts. This is always a good time to inspect the ‘shafts to ensure the splines are not twisted. In our case, everything looked perfect.

Once you disconnect the locker plug and removing the bearing caps, you can remove the carrier from the housing. If this were a standard (non-Rubicon) differential, you would mark the bearing caps to ensure each remained with the correct side.

To remove the pinion, first you’ll unbolt the driveshaft, then remove the pinion nut. Next, an air hammer is used to break the pinion free from the housing.

Something interesting to note is that the higher the gear ratio number, the smaller the pinion becomes in the Dana 44. On the right is the stock 3.73 pinion, while the new 5.13 pinion is on the left. There’s a slight trade-off in strength, but the gear ratio upgrade is well worth it.

The Nitro ring gear attaches to JK’s Tru-Lok carrier via the provided ring gear bolts. The bolts are dabbed with thread locker and then torqued to spec.

How the pinion contacts the ring gear is incredible important. Using a series of shims, the differential can be slid left or right, while a crush sleeve is used to set the pinion’s depth. Here, a dial gauge is used to check the backlash (the clearance between the pinion and ring gear teeth).

Since the JK uses a standard gear setup in the rear, the pinion powers the stronger side of the gear called the drive side. The opposite side of the gear is known as the coast side. The paint marks shown indicate how the pinion gear is contacting the ring gear teeth. The goal is to have a centered contact pattern with a little paint showing above and below the contact pattern.

Once the pattern is perfect, you can reinstall the differential cover. We’re using an X-treme series cover from Nitro. The aluminum cover adds extra fluid capacity and has a finned design to help aid in cooling (a critical necessity for differential longevity). Given the thickness of the cover, we also don’t have to worry about peeling it back if we do manage to tangle with a rock on the trail.

Another benefit of the cover is the high-mount fill hole and overflow port. This makes it easy to add fluid and prevents you from overfilling the diff.

Since the new differential gears require a 500-mile break-in period, we’re using a conventional 80-90w for the first fluid fill up. It recommends driving only for 30-minute intervals and allowing the diff to cool before driving again when first breaking in a new gearset.

For modern four-wheel drives such as our late-model Wrangler, you’ll need to recalibrate the vehicle's computer for the new differential ratio. Thankfully, we already had a JKS J-Cal programmer, which allows us to easily input the new ratio.